Lesson 2/learning Event 3

Considering the example described in this lesson, the determination of screen capacities would be as follows

(assume both screens are 40 square feet in area).

Top Screen = 3/4 inch

Q=BxAxDxHxOxW

B = 1.7 tph (Table 10)

A = 40 feet (Table 11)

D = 1.0 (Table 12)

H = 0.9 (Table 12), which is found as follows: 3/4" x 1/2 = 3/8" is the halfsize (see explanation below).

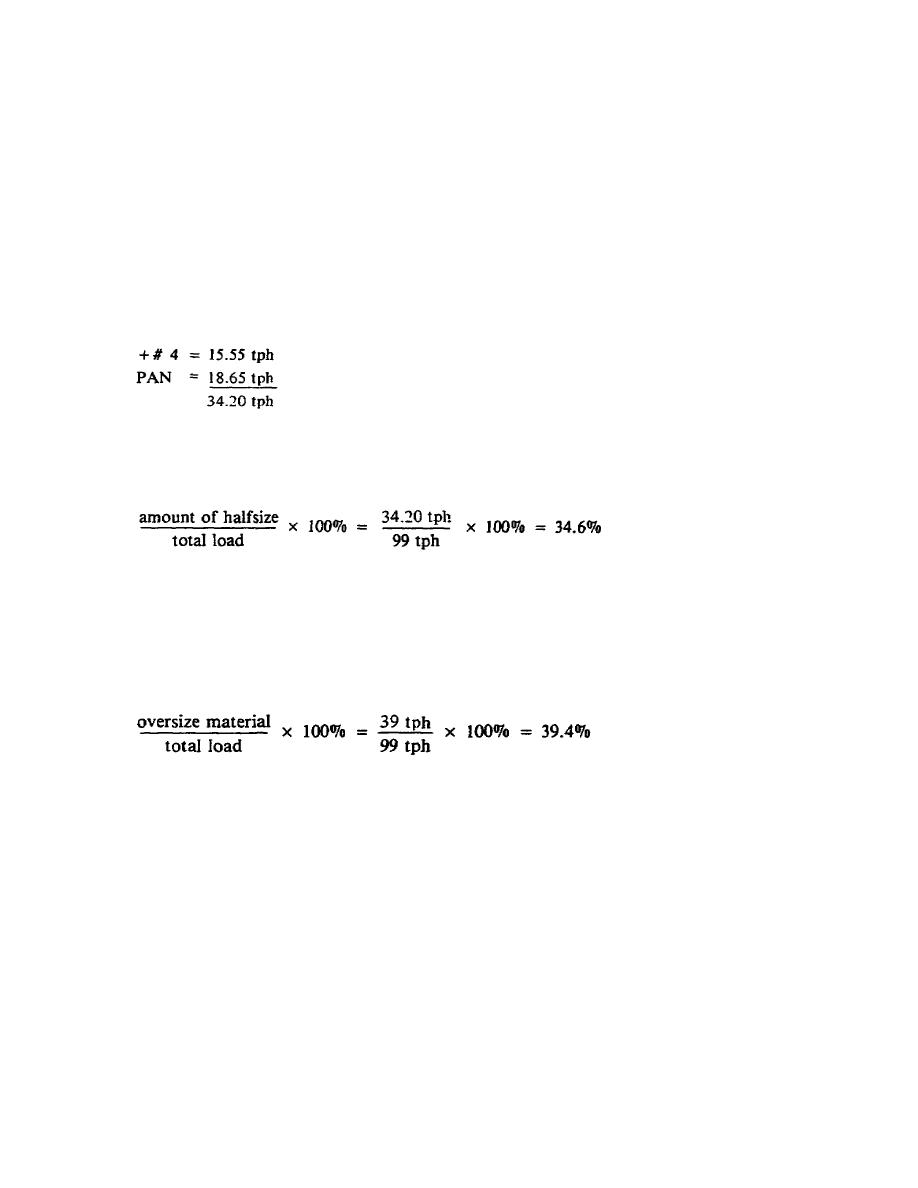

Tonnages can be found from the sieve analysis of the total product. In this case there are 34.2 tons in this range.

The flow into the top screen is the sum of the total jaw crusher output and the roll crusher output, or 60 tph + 39

tph = 99 tph. This is because 21 tons of the 60 tons pass through the top screen and 39 tons go to the roll crusher

for further processing. Percent halfsize is then:

The corresponding factor, H, is found by interpolation from Table 12 to be 0.90.

Oversize (O) is all material over 3/4 inch. The oversize factor is similarly found from percentage oversize using

information from the sieve analysis. Remember that for the top screen, whatever goes to the roll crusher (in

essence rejected) is oversize. Of the total screen load of 99 tph, 39 tph is oversize and must be sent to the roll

crusher:

From Table 12, by interpolation, the oversize factor when 39.4 percent of the feed is oversize equals 0.95.

Washing is not being done, so a factor of 1.0 is used (Table 12).

Therefore, for the top screen:

Q=BxAxDxHxOxW

Where: B = 1.7, A = 40, D = 1.0, H = 0.9, O = 0.95, W = 1.0

Q = (1.7) x (40) x (1.0) x (0.9) x (0.95) x (1.0) = 58.2 tph.

The top screen has the ability to screen out 58.2 tph. The screen must be able to let 60 tons pass through each

hour to keep up with the jaw crusher produc-

64

Previous Page

Previous Page