Lesson 2/Learning Event 3

Percent passing is then the difference between the percent passing of the previously larger range and the percent

retained for the desired size range. When starting the process at the largest size range, subtract the percent

retained from 100 percent.

Check the percent passing for each size against corresponding product specifications. In this case, you have met

the specifications.

SCREEN CAPACITY

The last equipment component to be checked is the screen assembly. Each screen must be checked to determine

whether or not the screen can handle the input flow to it. The larger the screen opening, the higher the capacity

will be.

The following formula is used to determine the capacity of a screen:

Q=BxAxDxHxOxW

Q = Quantity of material in tons per hour the screen can process.

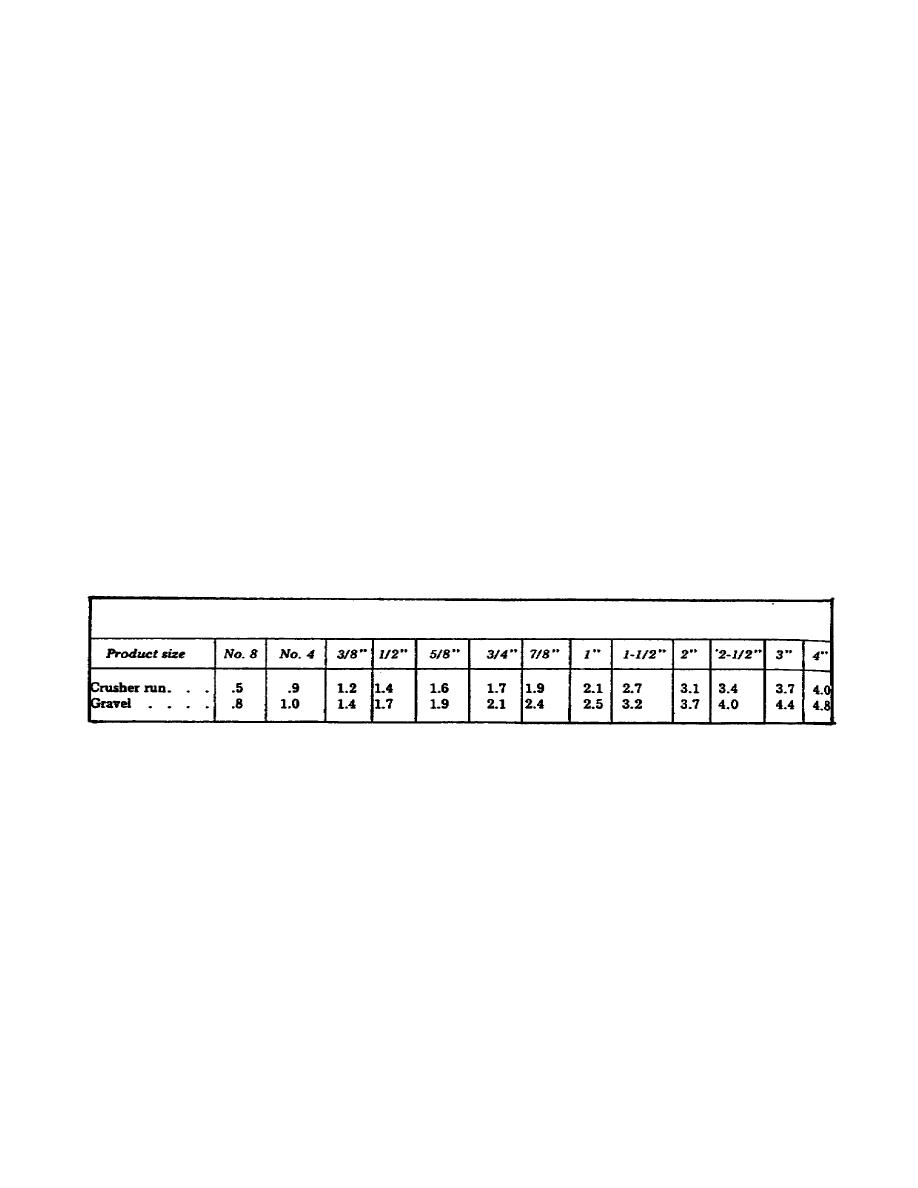

B = Basic capacity of one square foot of screen cloth (Table 10) in tons per hour. For example: one square

foot of 1 1/2-inch screen cloth has the ability to let 2.7 tons of crusher run rock pass through it in one hour. A

1 1/2-inch screen has the ability to pass 3.2 tph of gravel run material. The increase in production is due to

the more rounded particle shapes found in gravel deposits. Rounded particles will pass through a screen more

readily than angular particles.

TABLE 10. BASIC CAPACITY, B (tons/hour/square foot)

61

Previous Page

Previous Page