Lesson 2/Learning Event 3

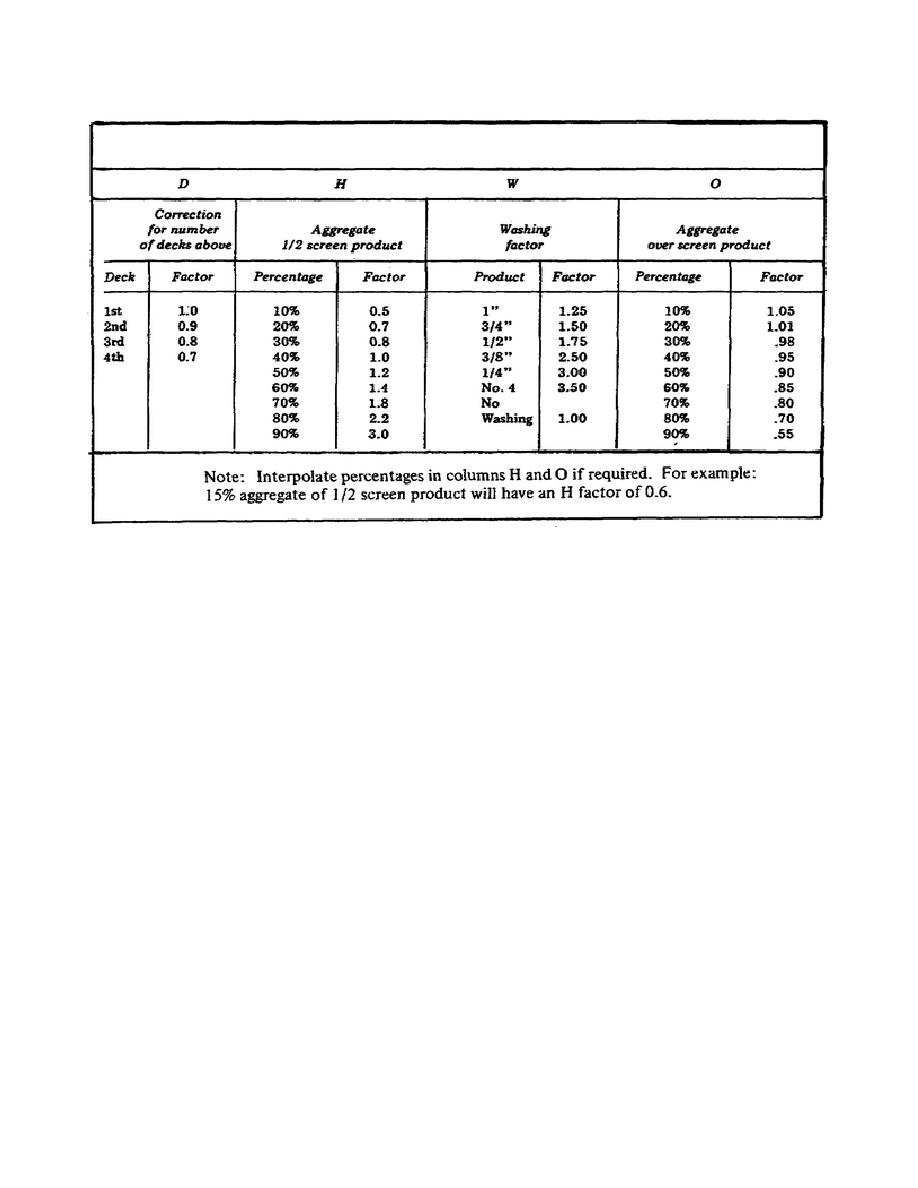

TABLE 12. SCREEN CORRECTION FACTORS

gregate. As the percentage of 1/2 size aggregate in the feed is increased, the capacity of the screen will

increase. This is because 1/2 size aggregate will pass through the screen openings much more readily than

aggregate greater than 1/2 size aggregate.

O = Oversize material. This is the aggregate (Table 12) that is too large to pass through a screen. As the

percentage of oversize aggregate in the feed is increased, the capacity of the screen will decrease. This is due

to the fact that the oversize particles, being heavier than the smaller particles, will fall to the bottom of the bed

of rock going across the screen. Since they are too large to pass through the screen, they tend to prevent the

smaller parties from passing through.

W = Washing factor (Table 12). When aggregate is sprayed with water as it passes across a screen, the

capacity of the screen will be increased. This is because the water will lubricate the outer surfaces of the

aggregate, thereby causing the aggregate to pass through a screen more readily than if it were dry. When

washing is not employed, a factor of 1 is used for the washing factor. Washing is most effective in the

smaller size ranges. As the aggregate size is increased, the advantage of washing is decreased. Care should

be taken in washing operations in that too little water will not flush out the dirt and mud washed off the rock.

If too little water is used this dirt and mud may clog up the screens thereby decreasing the screen capacity.

63

Previous Page

Previous Page