Lesson 3/Learning Event 2

To check this same piece for taper, first remove the V-block clamps. It is

only necessary to lay the piece in the blocks. Then follow the procedures

outlined above. Adjust the indicator to the proper height on the pedestal

and bring the button of the indicator to bear on one end of the workpiece.

Adjust the dial so the 0 on the dial lines up with the pointer of the

indicator.

Now move the indicator pedestal base so the button of the

indicator is brought to bear on the opposite end of the workpiece.

By

noting the deflection of the needle from 0, you can readily see the amount

of taper in the shaft.

Always mount the dial indicator with the plunger at right angles to the

object being measured.

Failure to do this can result in inaccurate

readings.

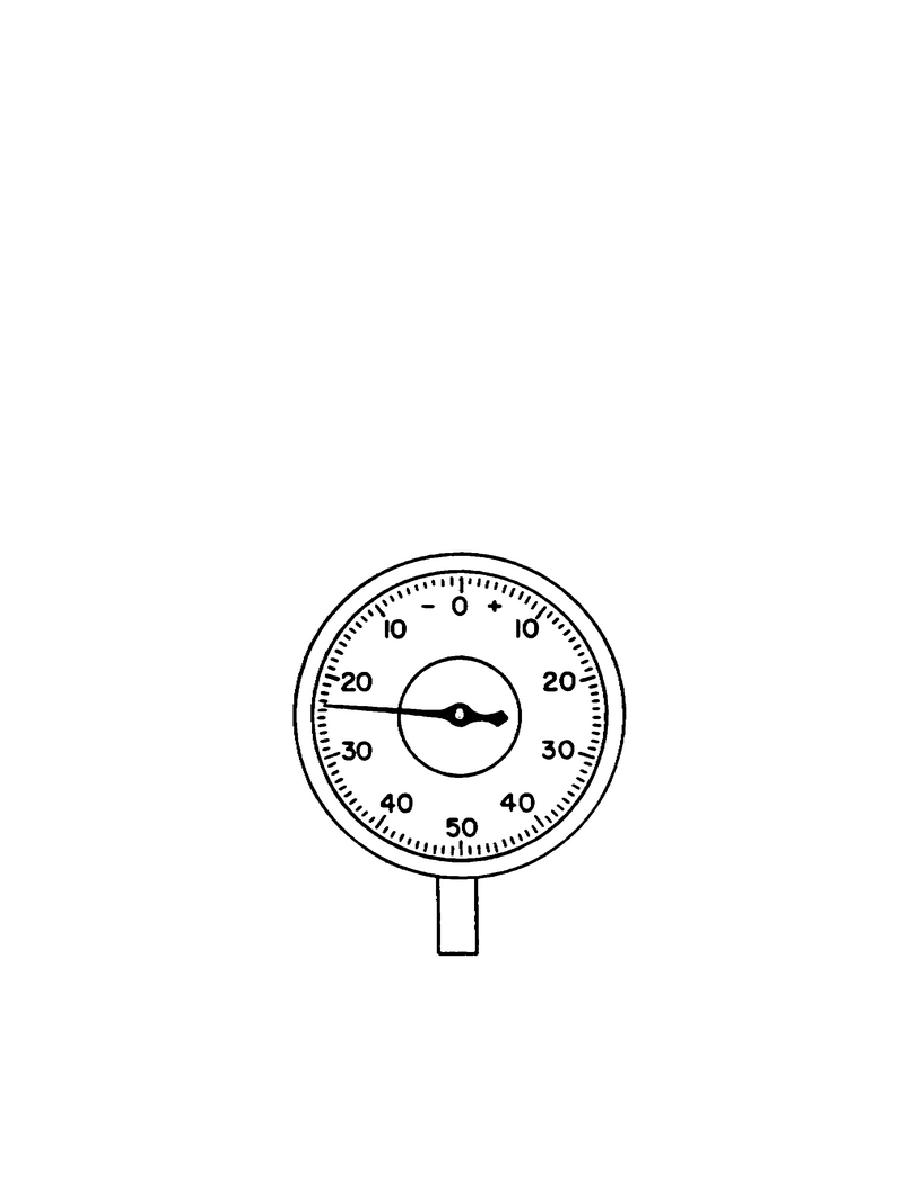

The value of the graduations on the indicator dial of the dial indicator is

easily determined. Using Figure 44 as an example, first look at the figure

on the dial face which identifies the indicator as a 1/1,000 type.

(The

figure is just below the center of the hand.)

Then count the number of

spaces between the 0 and the first numeral to the left of the 0. The first

numeral is a 10, indicating .010 of an inch (10/1,000) of plunger travel.

Since there are 10 spaces between the 0 and the 10, the value of each

graduation is equal to one-thousandth inch.

FIGURE 44.

DIAL INDICATOR

58

Previous Page

Previous Page