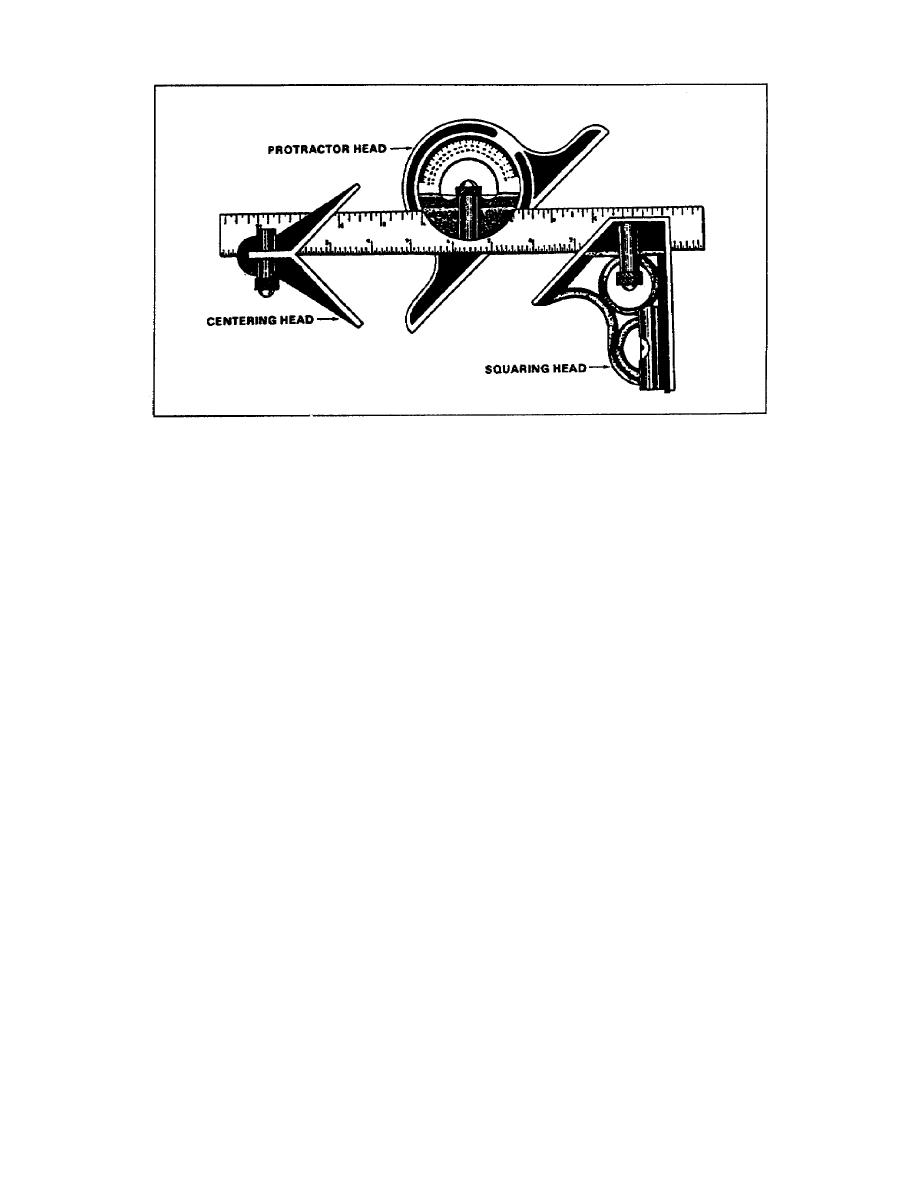

Figure 2.48.

Combination square

2-11. Sharpening and Smoothing Tools. Two main types of tools are

used to sharpen and smooth other tools: stones and files.

a. Grindstones. Most bench grinders found in carpentry shops are

equipped with two grinding wheels: one of coarse grit and one with

fine grit. Grinding wheels are held to the shaft by nuts, which

squeeze the wheel between two special side washers. Grinding wheels

are also rated by the turning speed they can withstand. Be sure you

use stones made to withstand the rated revolutions per minute of the

grinder electric motor. A tool rest is attached to the grinder frame

and is adjustable for height as well as for distance from the stone.

Most grinders are equipped with heavyduty glass guards to permit

watching as you grind. If there is no eye guard, you must wear

safety goggles to protect your eyes. It is considered poor practice

to use the side of the wheel for grinding. When the surface of the

stone becomes irregular or filled with metal particles, use a stone

dressing tool (Figure 249) to restore a good grinding surface. A

water container, attached to the base of the grinder, is used for

cooling parts being ground. Always cool the blades of tools you are

sharpening to prevent destroying the temper of the metal with the

excess heat generated from grinding. Heavy grinding is done on the

coarse wheel, and light or finishtype grinding is done on the fine

grit stone. Most cutting edges should be finished by hand, using a

fine oilstone.

EN5155

2-26

Previous Page

Previous Page