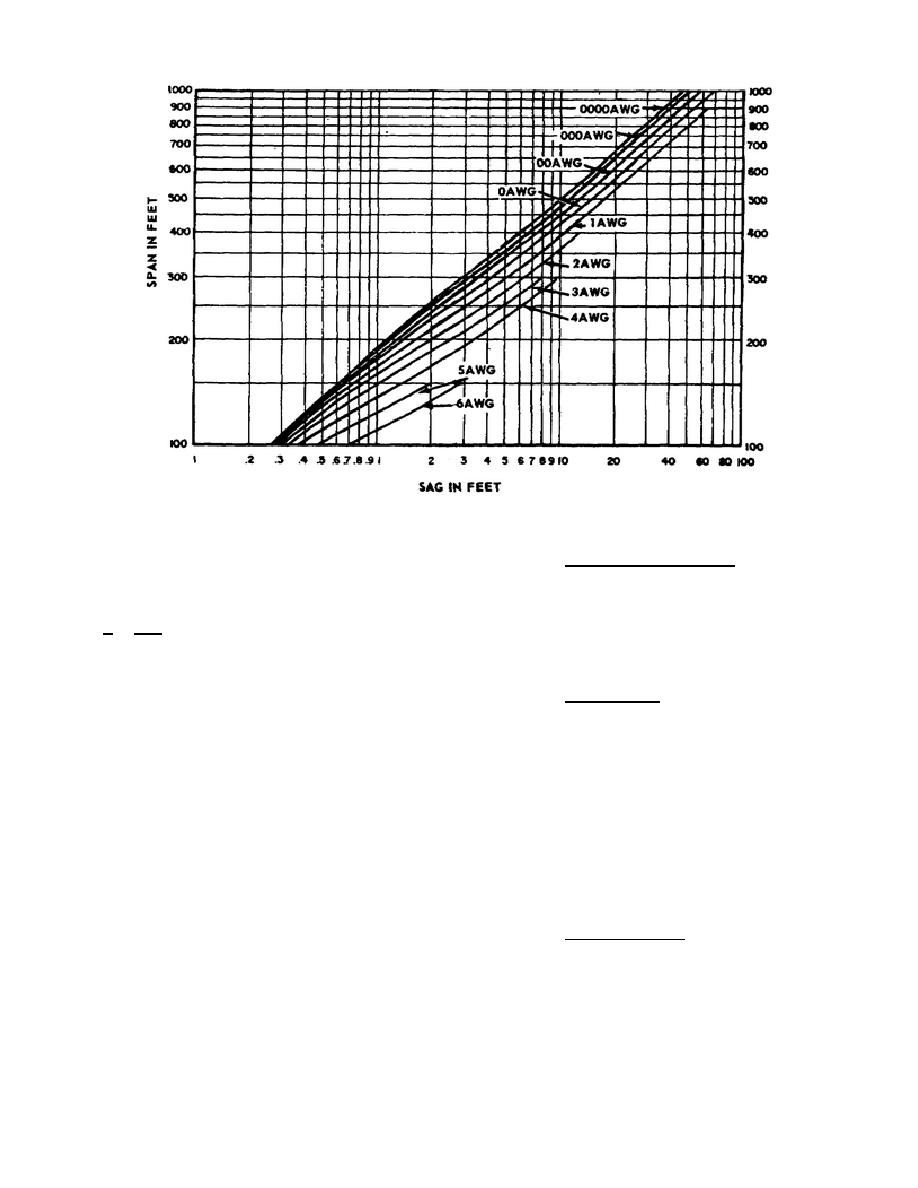

Figure 12.

Sag for one-half ultimate strength of bare hard-drawn copper

conductors.

account materials available, military

(1) Service drop wires.

Table 6

necessity, urgency of the project, and

gives the recommended sag for service

other factors.

drop wires.

Service drops should not

be pulled tighter than indicated by

f. Sag.

Sag

is

the

maximum

the table, except to obtain necessary

departure of a wire in a given span

clearances; sags must never be less

from the straight line between the two

than half those shown.

points of support (fig 11).

Check

sags carefully.

Lift wires free of

(2) Long spans.

Tables 5 and 6

the arm to permit the sags to equalize

have a maximum span given of 150 feet.

when

installing

conductors.

The

This length is normally used for TO

common tendency is to pull small

installations.

However, for high-

copper conductors too tight and to

tension transmission lines much longer

leave

too

much

sag

in

large

spans

will

be

employed.

For

conductors.

When the small wires are

determining sags for spans over 150

pulled too tight, they are likely to

feet, use figure 12 which gives the

break in cold weather or during ice

corresponding sags at a fixed mean

temperature of 60oF. The sags given by

storms.

If they do not break, they

may

stretch,

reducing

the

cross

this figure allow the conductors to be

section of the wire.

Tables 5 and 6

stressed to one-half of their ultimate

give the amount of sag to be used

tensile strength.

ordinarily for line conductors in

distribution systems.

Sags given are

(3) Excessive sag. Excessive sag

such that the conductors will not be

may

often

be

found

on

overstressed under conditions of ice

existing overhead installations, but

and wind.

the

cause

for

the

excess

should

2-18

Previous Page

Previous Page