because they are of poor quality and are subject to

the projection on one edge at the bottom and at the

much waste.

top of the piece on the other edge. In this way

adjacent boards overlap each other to form a joint.

c. Surfacing and Working Lumber. Lumber

is further classified according to the manner in which

Patterned

(c) Patterned lumber.

it is milled.

lumber is cut in many designs and is used for trim.

(1) Surfacing. Lumber Is classified as

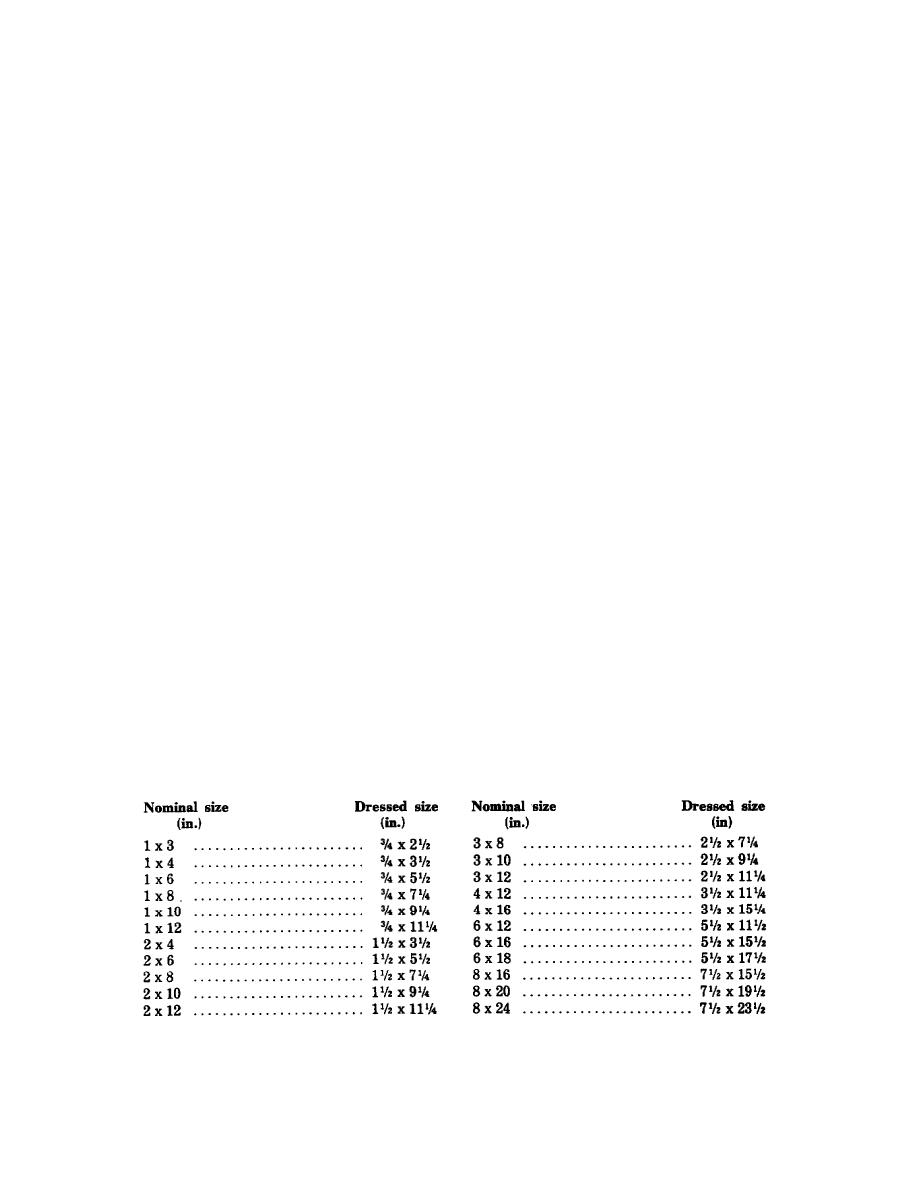

d. Actual and Nominal Sizes of Lumber.

rough or dressed, according to the amount of planing

Sizes of lumber are specified by nominal dimensions

done in the mill.

which differ from the actual dimensions of the milled

pieces. When lumber is run through a saw and

(a) Rough. Rough lumber is as it

planer, it nominal size remains the same but its actual

emerges from the saw, or unplaned; the abbreviation

size is reduced by the amount of surfacing it

RGH indicates rough lumber.

undergoes. Approximately 1/4 inch is planed off

each side in surfacing. Lumber is also divided into

(b) Dressed. Dressed, or surfaced,

groups according to size, namely: strips, pieces less

lumber is the rough lumber after it has been run

than 2 inches thick and under 8 inches wide; boards,

through a planer. It may have any combination of

less than 2 inches thick and more than 8 inches wide;

edges and sides dressed, such as S1S, surfaced on one

dimensional lumber, 2 to 6 inches thick and of any

side; S2S, surfaced on two sides; S1S1E, surfaced on

width; and timber, 6 or more inches in the least

one side and one edge; and S4S, surfaced on four

dimension. Dimensions of some common sizes are

sides.

given in table 2-1.

(2) Worked lumber. Worked lumber has

been run through a machine such as a matcher,

2-7.

LIGHT FRAMING

shaper, or molder. It can be matched, shiplapped, or

patterned.

There are three principal types of framing for

light structures: western, balloon, and braced. Figure

Matched

2-9 illustrates these types of framing and specifies the

(a) Matched lumber.

lumber is cut so that it interlocks. A common type is

nomenclature and location of the various members.

tongue and groove (T&G), in which a groove is cut in

one edge and a mating bead, or projection, is cut on

a. Western Frame. The western or platform

the other edge. Boards are frequently dressed and

frame (1, fig 2-9) is used extensively for military

matched (D&M) with the tongue and groove in the

construction. It is similar to the braced frame, but

center, making the pieces center-matched.

has boxed-sill construction at each floor line. Also

note that cross bridging is used between the joists and

(b) Shiplapped lumber. Shiplapped

pieces are cut with a square step on either edge and

Table 2-1. Nominal Sizes and Dressed Sizes of Lumber (New Standard)

50

Previous Page

Previous Page