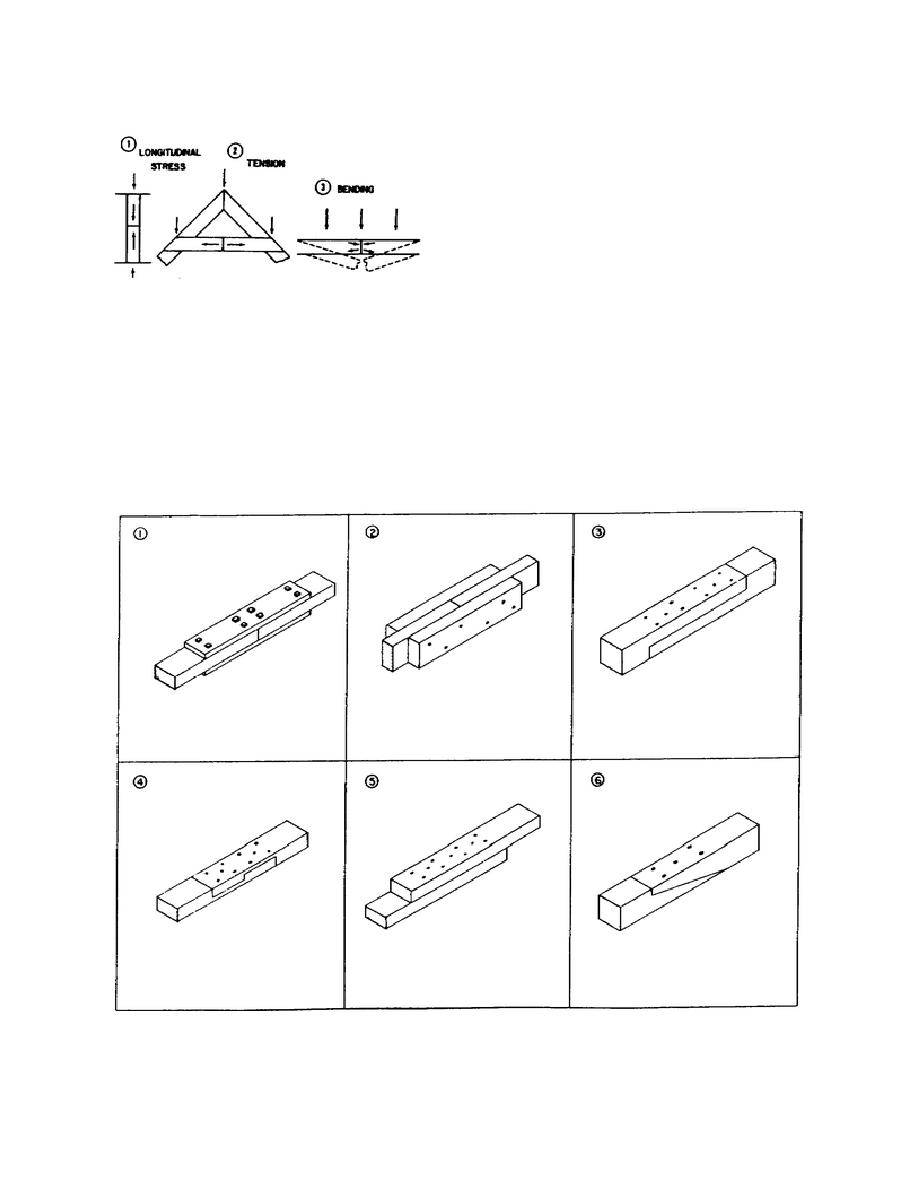

(2) Plain splice. A hasty substitute for

the square splice is the long plain splice (5, fig. 1-11).

A long overlap of the two pieces is desirable to

provide adequate bearing surfaces and room for

enough nails or other fasteners to compensate for the

lack of shoulder lock.

c. Bend-resistant splices.

Horizontal

timbers supporting weight are subject to compression

of the upper side that has a tendency to crush the

Figure 1-10. Splice stresses.

fibers, and to tension along the lower side that tends

to pull the fibers apart as shown diagramatically in 3,

1-10). Tension splices are designed to provide

figure 1-10. The bend-resistant splice designed to

increased bearing surface and additional shoulders

meet these conditions is constructed by cutting

within the splice to resist the buckling tension.

oblique complementary tongues or laps in the ends of

two pieces of timber (6, fig. 1-11). To absorb

(1) Square splice. The square splice is

compression stress, the end of the upper tongue is cut

a modification of the compression-resistant halved

square to butt against a corresponding square step or

splice. Complementary notches are cut in the

shoulder at the base of the complementary lower

tongues to provide an additional locking shoulder (4,

tongue. The end of the lower tongue is

fig. 1-11). It may be greatly strengthened by adding

fishplates or scabs.

Figure 1-11. Compression, tension, and bending-resistant splices.

1-14

Previous Page

Previous Page