TC 9-62

TESTING ELECTRONIC EQUIPMENT

4-135. The two most widely used checks in testing electronic equipment are VISUAL and

SIGNAL TRACING. The importance of the visual check should not be underestimated

because defects can be found right away, simply by looking for them. A visual check does

not take long; in fact, you should be able to see the problem in about two minutes if it is

the kind of problem that is visible. Learn the visual check procedures found in Table 4-2

because you will find yourself using them quite often. This procedure is not only good for

power supplies but also for any type of electronic equipment you may be troubleshooting.

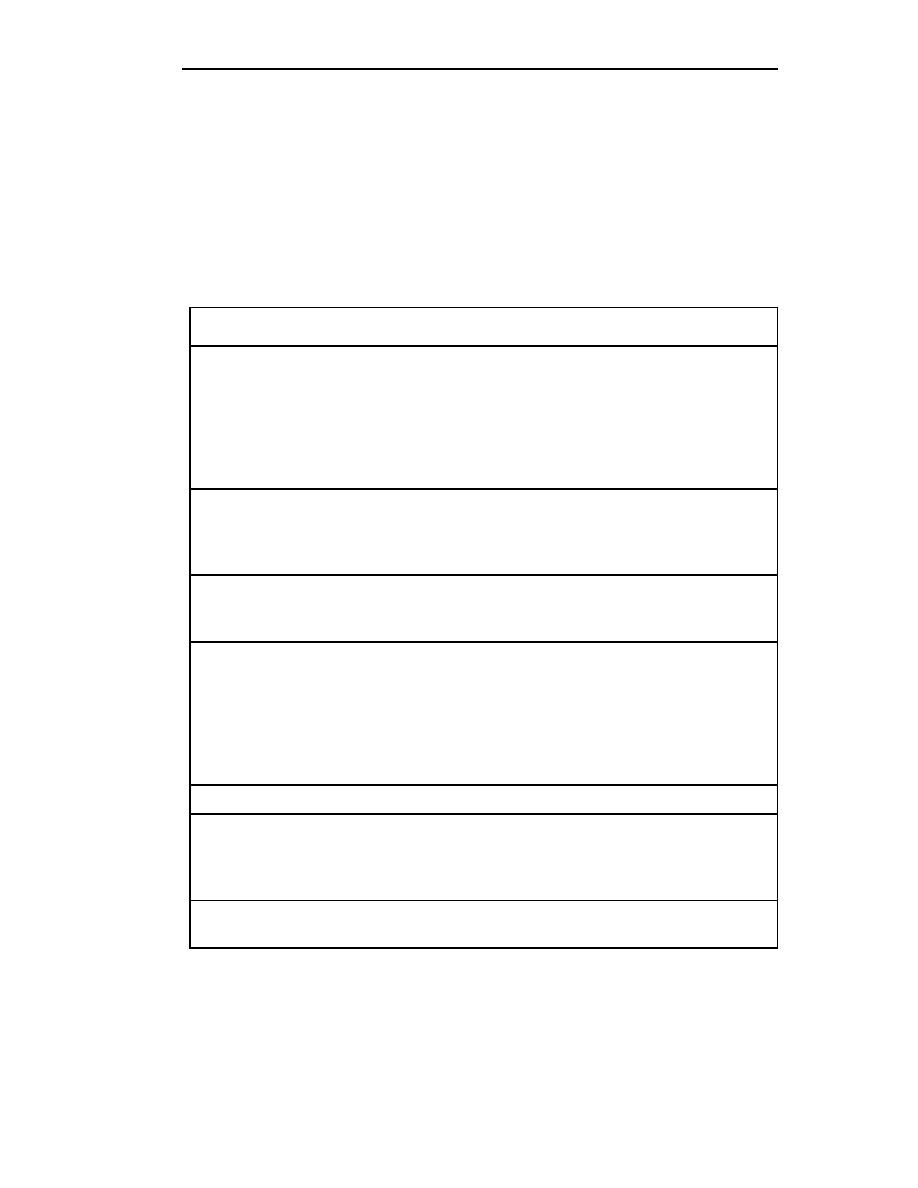

Table 4-2. Visual Check Procedures

BEFORE YOU PLUG IN THE EQUIPMENT, LOOK FOR:

SHORTS - Any terminal or connection that is close to the chassis or to any other

terminal should be examined for the possibility of a short. A short in any part of

the power supply can cause considerable damage. Look for and remove any stray

drops of solder, bits of wire, nuts, or screws. It sometimes helps to shake the

chassis and listen for any sounds of rattling. Remember to correct any problem

that may cause a short circuit. Even though it is not causing trouble now, fix it; it

may cause problems in the future.

short somewhere. Locate the short. If the equipment has a fuse, find out why the

fuse did not blow. Sometimes a fuse that is too large may have been installed or

there may be a short across the fuse holder.

LOOSE, BROKEN, OR CORRODED CONNECTIONS - Any connection that is not in

good condition is a trouble spot. Even if it is not causing trouble now, fix it; it will

probably cause problems in the future.

DAMAGED RESISTORS OR CAPACITORS - A resistor that is discolored or charred

has been subjected to an overload. An electrolytic capacitor will show a whitish

deposit at the seal around the terminals. Check for a short whenever you notice a

damaged resistor or a damaged capacitor. If there is no short, the trouble may be

that the power supply has been overloaded in some way. Make a note to replace

the part after signal tracing. There is no sense in using a new part until the trouble

has been located.

AFTER YOU PLUG IN THE POWER SUPPLY, LOOK FOR:

SMOKING PARTS - If any part smokes or if you hear any boiling or sputtering

sounds, pull the plug immediately. There is a short circuit somewhere that you

have missed in your first inspection. Use an ohmmeter to check the part once

again. Start in the neighborhood of the smoking part.

SPARKING - Tap or shake the chassis. If you see or hear sparking, you have located a

loose connection or a short. Check and repair.

4-136. If you locate and repair any of the defects listed in Table 4-2, make a note of what

you find and what you did to correct the defect. It is quite probable you have found the

trouble. However, you must not take anything for granted. You must prove to yourself that

the equipment is operating properly and that no other troubles exist.

4-44

TC 9-62

23 June 2005

Previous Page

Previous Page