Lesson 2/Learning Event 3

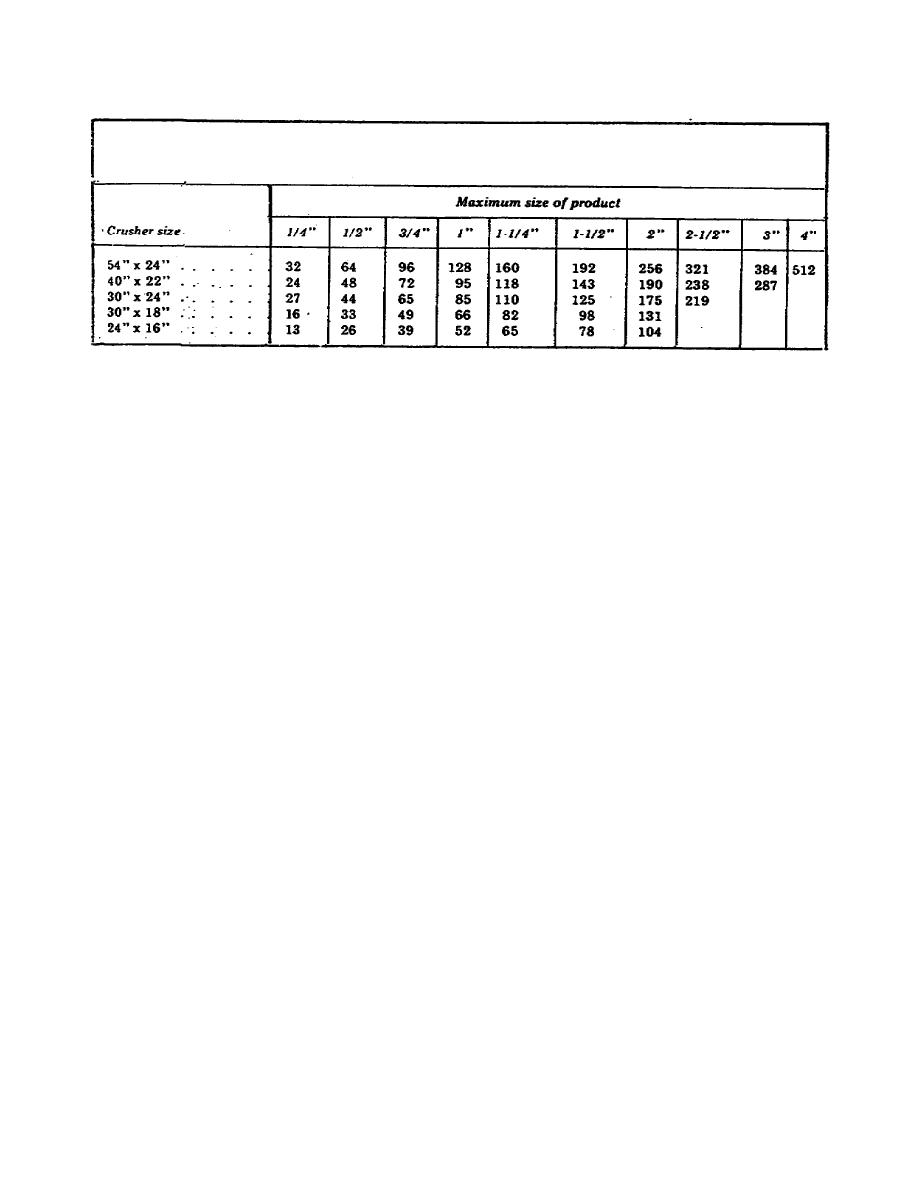

TABLE 7. ROLL CRUSHER CAPACITY (tons per hour)

SIEVE ANALYSIS

After the production rates are determined for the jaw and roll crushers, the next step is to make a theoretical sieve

analysis. This is to determine the percentage breakdown of the various sizes of material produced. It should be

remembered that in any crushing operation, sizes will be produced from the maximum product size down to dust

to include all sizes in between. The purpose of the sieve analysis is to calculate how many tons of various size

aggregate will be produced from the jaw crusher action and the roll crushing action. From this the actual amount

of product size aggregate (3/4 inch to 3/8 inch, in this example) that will be produced each hour can be

determined.

The jaw crusher has been set to produce maximum size particles of 2 1/2 inches in the primary crushing operation

of this example. But material ranging from 2 1/2 inches down to dust particles will result. The roll crusher has

been similarly adjusted to produce particles ranging from 3/4 inch (top roll product size) down to dust. Tables 8

and 9 have been developed to show the percentage breakdown of each particle size produced based on the

particular crusher setting.

Because the screens receive material from both crushers, a sieve analysis must be done for both crushers. Each

particle size in the specifications from top product size down to the lowest specified size must be analyzed, plus

material in the pan is included. NOTE: Pan is the by-product that goes through all the sieves but must be included

in the sieve analysis for 100% of the aggregate crushed.

55

Previous Page

Previous Page