Lesson 2/Learning Event 3

Learning Event 3

CALCULATING PLANT PRODUCTION

Once you have properly calibrated your plant, production will be maximized. Not much else can be done to

improve the hourly output. For planning and estimation purposes, the remaining six steps of the production

determination procedure must be accomplished to get an idea of what the production will be. This information is

essential for your responsibilities as planner and manager.

JAW CRUSHER PRODUCTION RATE

The jaw crusher capacity depends upon the size of the jaw crusher, the type of rock being processed, and the

product setting. In this example the jaw crusher size is 20 x 36 inches and you have already set the product

setting at 2 1/4 inches. Table 5 can be used to determine the capacity of the jaw crusher.

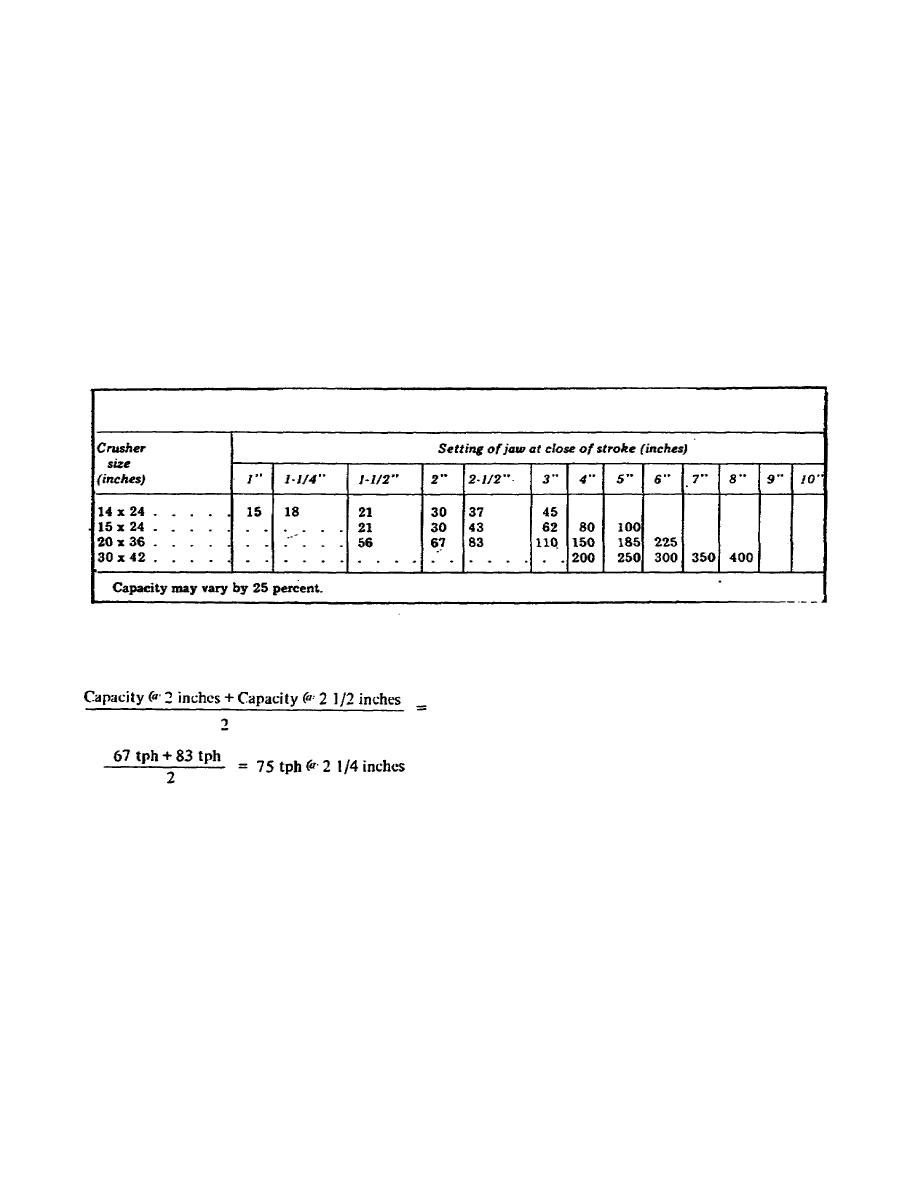

TABLE 5. JAW CRUSHER CAPACITY (tons per hour)

Table 5 relates the unadjusted jaw crusher capacity in tons per hour to the crusher size and the jaw (or product)

setting. Since there is no 2 1/4 inch reference in the table, interpolate the capacity as follows:

53

Previous Page

Previous Page