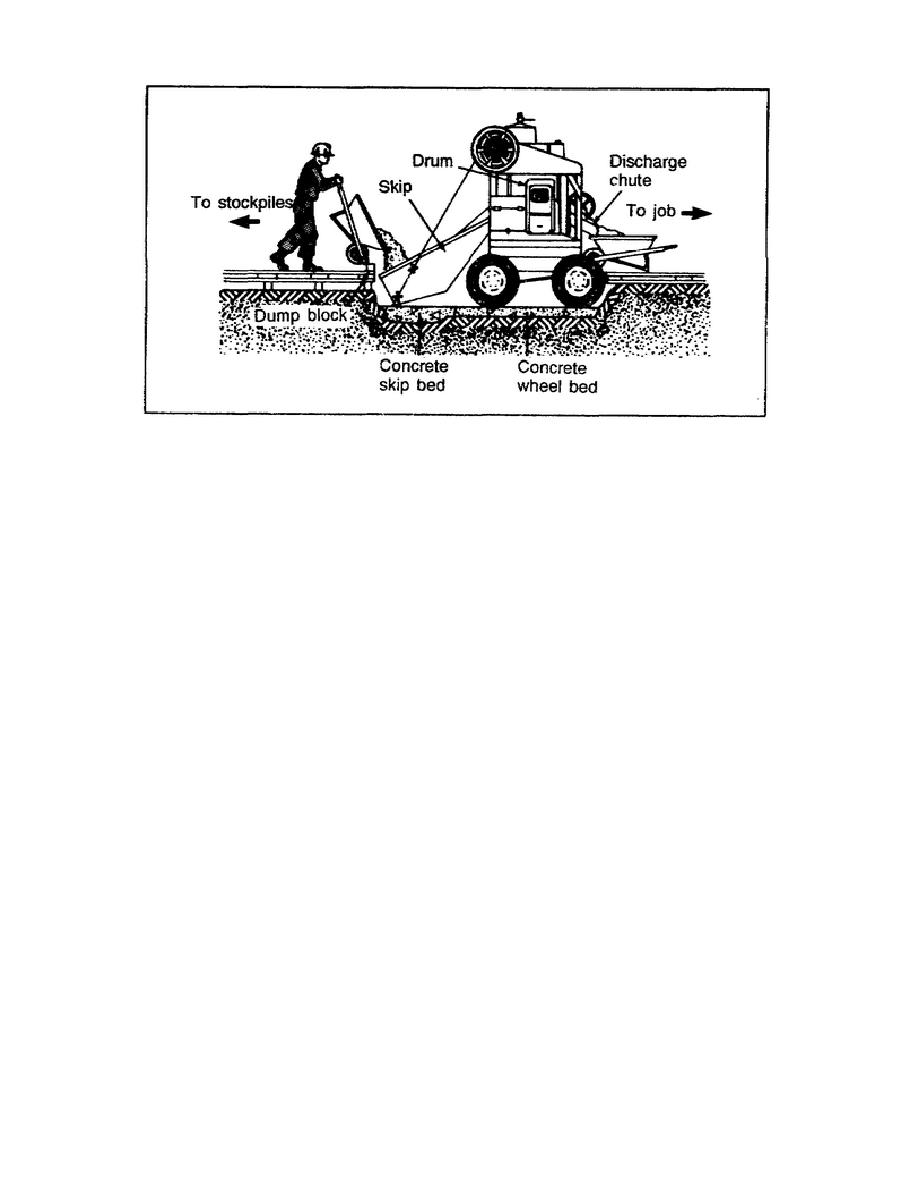

Figure 4-4. Charging mixer with mechanical skip.

into place to receive the concrete from the drum. Concrete that is somewhat dry tends to cling to the top

of the drum and not drop onto the chute in time. Very wet concrete may not carry up high enough on the

drum to drop onto the chute. You can correct these problems by adjusting the mixer speed. Increase the

speed for very wet concrete and decrease the speed for dry concrete.

Mixing time. The mixing time starts when water runs into the dry mixture, which should be during the

first quarter of the mixing period. The minimum mixing time per batch of concrete is 1 minute, unless the

batch exceeds 1 cubic yard. Each additional 1 cubic yard of concrete, or fraction thereof requires an

additional 15 seconds of mixing time.

Cleaning and maintaining the mixer. Clean the mixer daily if it operates continuously or following each

period of use if it operates less than 1 day. The exterior cleaning process goes faster if you coat the

outside of the mixer with form oil before you use it. Knock off all accumulated concrete on the mixer

exterior and wash it down with a hose. Mixer blades that are worn or coated with hardened concrete

provide less efficient mixing action. Replace badly worn blades, and do not allow hardened concrete to

accumulate in the mixer drum. Clean it out whenever you shut it down for more than 1 1/2 hours. To do

this, place a volume of coarse aggregate equal to one-half the mixer capacity in the drum and allow it to

revolve for about 5 minutes. Then discharge the aggregate and flush out the drum with water. Never

strike the discharge chute, drum shell, or skip to remove aggregate or hardened concrete because concrete

adheres more readily to dents and bumps.

Operating the M919 Concrete Mobile Mixer Unit

The concrete mobile mixer unit is a combination material transporter and on-site mixing plant. Table 4-2 on page

4-10 gives its physical characteristics and overall dimensions. The special body is mounted on an M900 truck

chassis. The unit carries enough unmixed material to produce up to 8 cubic yards of fresh concrete. Because the

unit is precisely calibrated, you can produce mixes that meet or exceed both the ACI and American Association of

State Highway and Transportation Officials' (AASHTO) standards for design strength. The unit operates on

either an intermittent or continuous basis, although continuous operation depends on raw material availability at

the site. Certain control settings for the mix operations vary from truck to truck and from site to site.

4-9

EN5466

Previous Page

Previous Page