materials at a batching plant and mix the concrete enroute to the job site. Trailer-mounted mixers are

commonly used to patch concrete pavements and for fillets and curve widening during pavement

construction. A battery of trailer-mounted mixers can serve either as a central mix plant for large-scale

operations or in conjunction with a central mix plant.

Operating the 16-Cubic-Foot Mixer

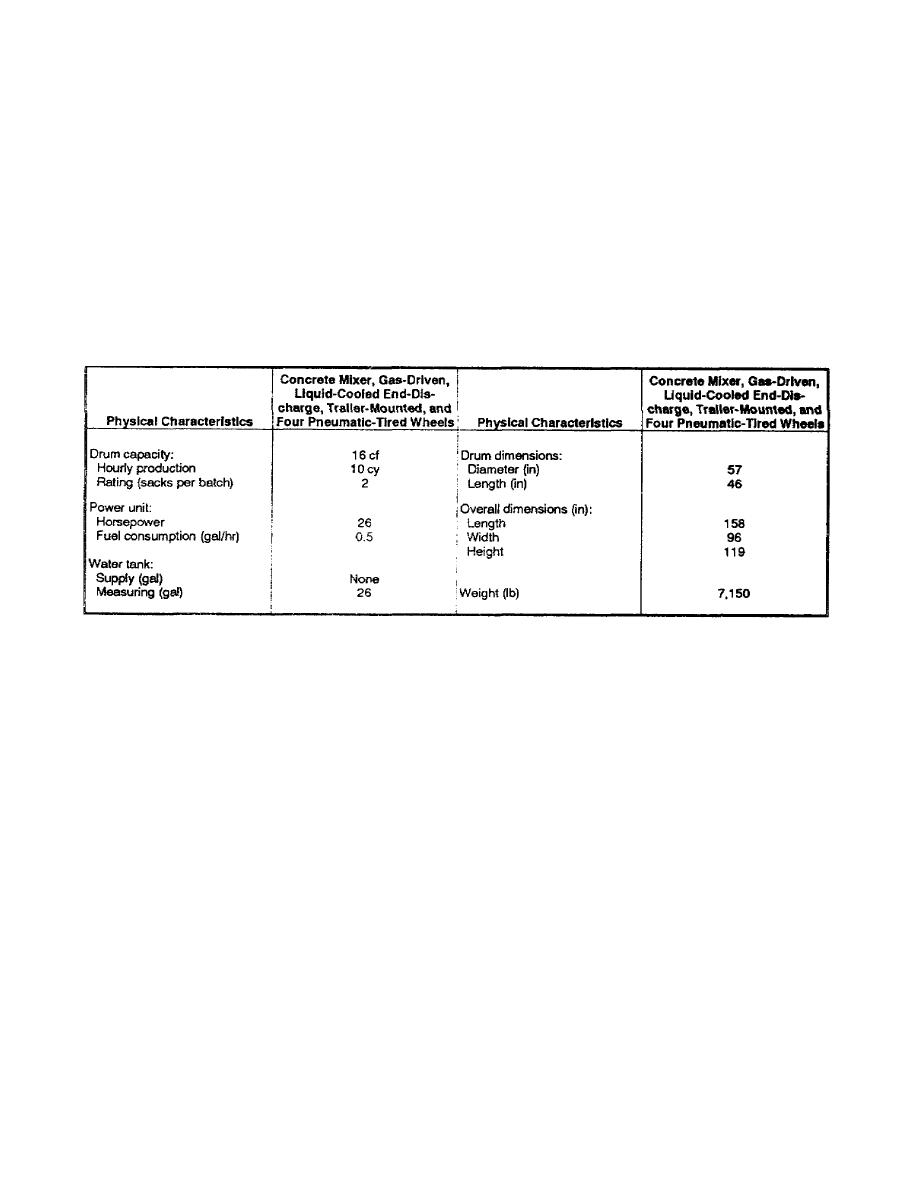

Table 4-1 gives the physical characteristics of a typical 16-cubic-foot mixer. You need ten soldiers and one

noncommissioned officer for normal operation of such a mixer. The crew handles the aggregate, sand, cement

and water and also operates the mixer. The noncommissioned officer supervises the overall operation. The crew

should produce about 10 cubic yards of concrete per hour, depending on their experience, the location of

materials, and the mixer's discharge rate. You would need at least one platoon to operate the overall project

pictured in Figure 4-3 on page 4-7.

Table 4-1. Physical characteristics of a typical 16-cubic-foot mixer.

Charging the mixer. You can charge mixers in two ways: by hand or with a mechanical skip (see Figure

4-4), which most mixers have. When using the skip, first deposit the aggregate, cement, and sand (in that

order) into the skip, and then dump it into the mixer while mixing water runs into the mixing drum. You

can place the sand on top of the pile in the skip so that you do not lose too much cement as the batch

dumps into the mixer. A storage tank on top of the mixer measures the mixing water into the drum a few

seconds before the skip dumps. This discharge also washes down the mixer between batches.

EN5466

4-8

Previous Page

Previous Page