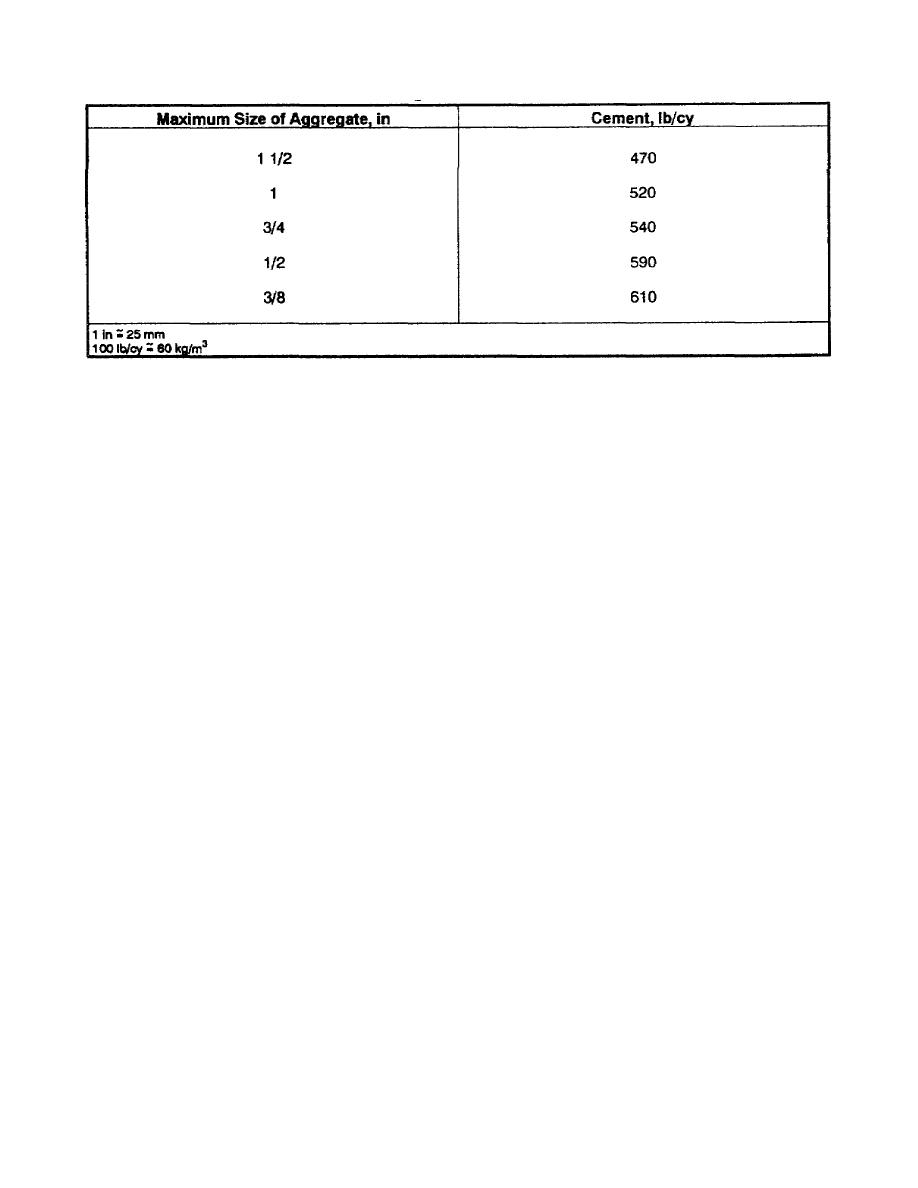

Table 2-7. Minimum cement requirements for concrete used in flatwork.

PART D - ADJUSTMENTS TO THE ORIGINAL DESIGN

ADJUSTMENTS FOR MOISTURE ON AGGREGATES

The initial mix design assumes that the aggregates are saturated and surface-dry (SSD); that is, neither the fine nor

the coarse aggregates have any fee water on the surface which would be available as mixing water. This is a

laboratory condition and seldom occurs in the field. The actual amount of water on the sand and gravel can only

be determined from the material at the mixing site. Furthermore, the moisture content of the aggregates will

change over a short period of time; therefore, their condition must be monitored and appropriate adjustments

made, as required. A good field test for estimating the free surface moisture (FSM) on fine aggregates follows.

Coarse aggregates are free draining and rarely hold more than 2 percent (by weight) FSM even after heavy rains.

FIELD TEST FOR MOISTURE DETERMINATION ON SAND

Sands used as fine aggregate in concrete may contribute a significant amount of moisture to the concrete mix.

This moisture must be accounted for by decreasing the mixing water added to the dry materials at the mixer, to

maintain the w/c ratio the concrete design calls for. The following procedure can be used as a field test for

estimating the amount of moisture on the sand. This procedure allows for some variation in estimating therefore,

the percentage of moisture determined is somewhat judgmental.

Procedure

The samples used for this test should be taken from a depth of 6 to 8 inches below the surface of the piled sand.

This negates the effect of evaporation at the surface of the pile.

A sample of sand is squeezed in the hand. Open the hand and observe the sample. The amount of FSM can be

estimated from the criteria below.

Damp sand (0 to 2 percent FSM). The sample will tend to fall apart. The damper the sand, the more it

will cling together. (See Figure 2-5 on page 2-20.)

2-19

EN5466

Previous Page

Previous Page