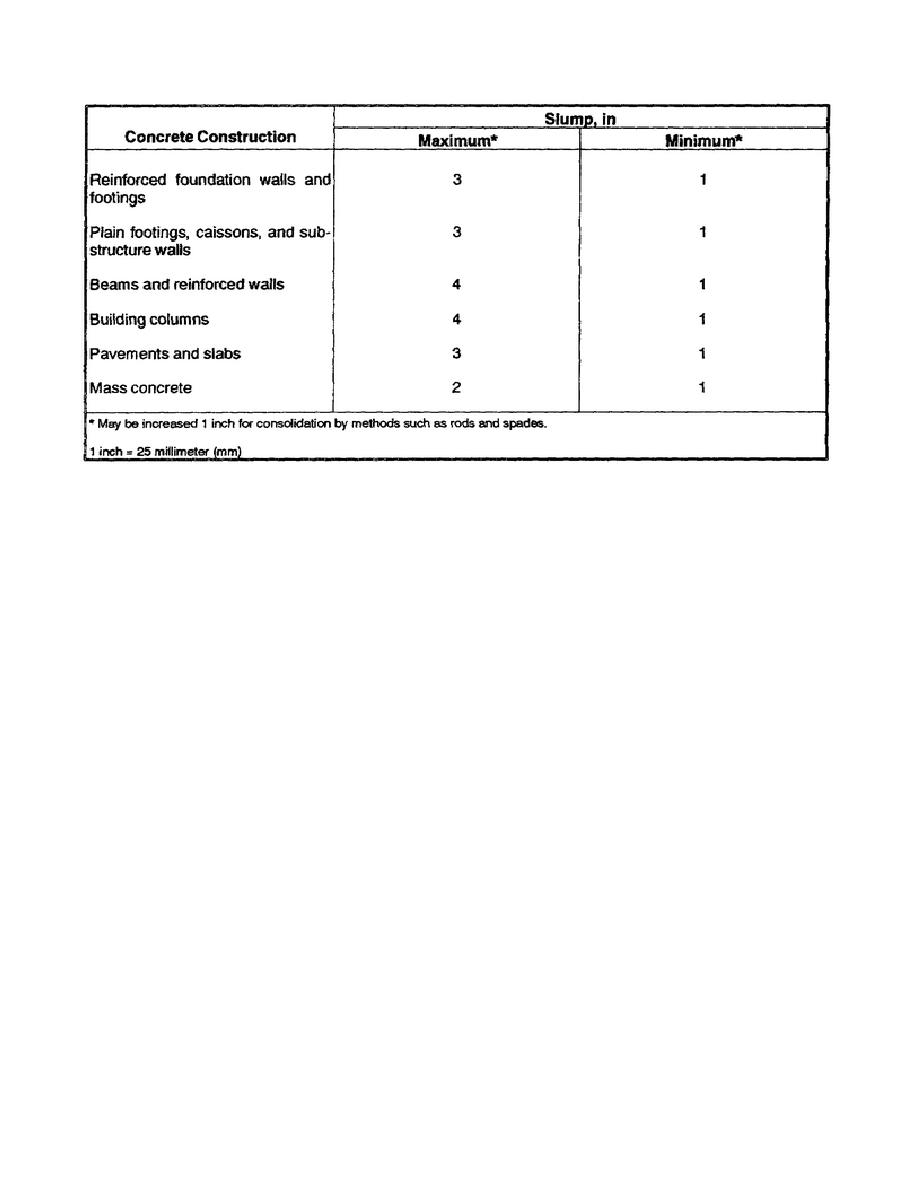

Table 2-4. Recommended slumps for various types of construction (with vibration).

PART B - TRIAL BATCH METHOD

DETERMINING WATER/CEMENT RATIO

With the w/c amounts determined, add sand and gravel to yield a workable mix. Record the data and repeat the

procedure until the concrete has desirable characteristics and a minimum cement content is obtained. This

method should be performed well in advance of a project. In the trial batch method of mix design, use actual job

materials to obtain mix proportions. The size of the trial batch depends on the equipment and how many test

specimens are made. Batches using 10 to 20 pounds of cement may be big enough, although larger batches

produce more accurate data. Use machine mixing if possible, since it nearly represents job conditions. Always

use a machine to mix concrete containing entrained air. Be sure to use representative samples of aggregate,

cement, water, and air-entraining admixture in the trial batch. Prewet the aggregate and allow it to dry to a

saturated, surface-dry condition. Place the sample in covered containers to maintain this condition until it is used.

This simplifies calculations and eliminates error caused by variations in aggregate moisture content. When the

concrete quality is specified in terms of the w/c ratio, the trial batch procedure consist basically of combining

paste (water, cement, and usually entrained air) of the correct proportions with the proper amounts of fine and

course aggregates to produce the required slump and workability. Calculate the larger quantities per sack or by

cubic yard.

USING TRIAL BATCH METHOD (EXAMPLE)

Determine the mix proportions for a concrete retaining wall with the footer exposed to fresh water in a severe

climate. The required compressive strength (f 'c is 3,000 psi at 28 days. The minimum wall thickness is 8 inches,

with 2 inches of concrete covering the reinforcement. Enter all trial mix data in the appropriate blanks on the trial

data worksheet in Figure 2-1 on page 2-8. Table 2-1 on page 2-3, indicates that a maximum w/c ratio of 0.50 by

weight satisfies the exposure requirements. Using Type IA (air-entrained) portland cement and a compressive

strength of 3,000 psi, Table 2-2 on page 2-4, shows that a maximum w/c ratio of approximately

EN5466

2-6

Previous Page

Previous Page