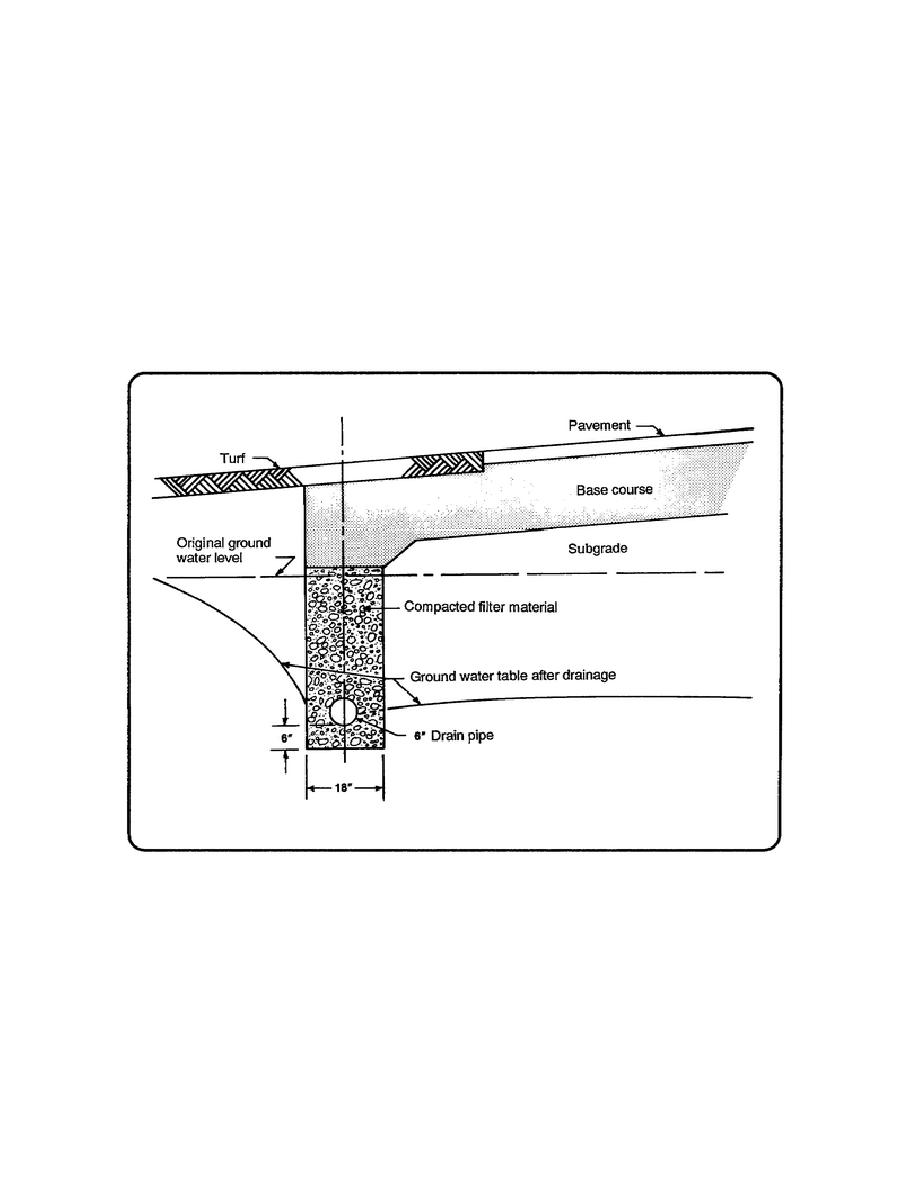

SUBSURFACE PIPE OR SUBGRADE DRAINAGE INSTALLATIONS

In cases where a V-type or other open-ditch type drainage system is not practical, it may be necessary to resort to

a subsurface piping system utilizing one of the many forms of pipe currently available. Care in construction is

essential during every stage of subsurface drainage construction. This prevents damage to base courses from

seasonal fluctuations of ground water. Failure of the subsurface system stemming from improper control of

grade, bedding, placement of pipe, placement of filter material, and other installation work gives no warning

before failing and is extremely difficult to repair when failure is discovered.

The most common form of subsurface piping is perforated pipe. Where the perforations do not extend completely

around the circumference of the pipe, the pipe is generally laid with the holes down and with the joints closed.

Materials used in the manufacture of this type of pipe are corrugated metal, cast iron, vitrified clay, nonreinforced

concrete, bituminized fiber, and asbestos-cement. Figure 6-5 shows how subgrade drainage lowers the ground

water table in a construction area.

Figure 6-5. Subsurface drainage installations

MOVE THE PROJECT

Moving the project to a drier location is the last alternative. However, as the engineer on a construction project

you may find that it is less costly to move the project than to install elaborate subsurface drainage systems.

EN5465

6-8

Previous Page

Previous Page