-- The slope of the culvert is 0.005 ft/ft or 0.5 percent.

-- The depth of fill at the critical section is 65 feet (rounded to the nearest tenth of a foot.

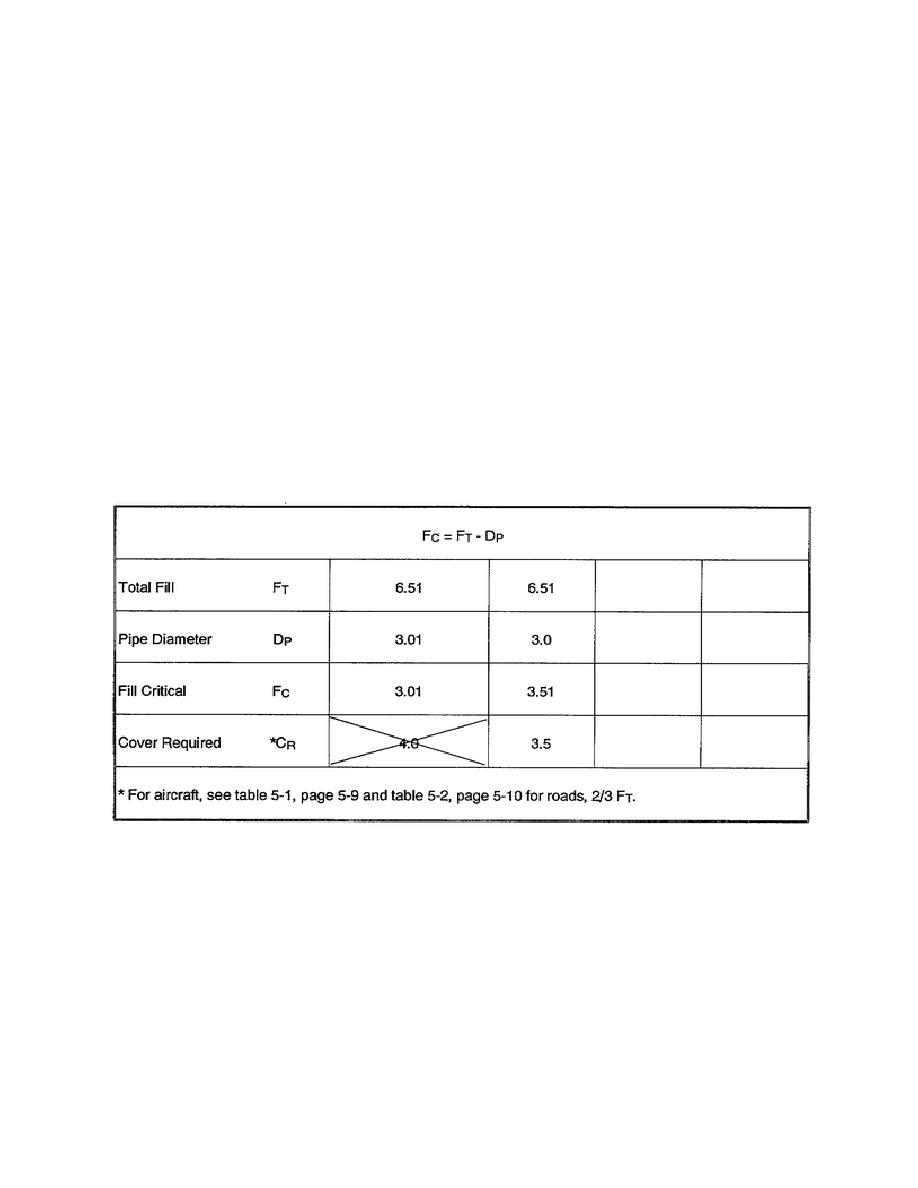

STEP 4. Determine the largest pipe for the fill. Prepare a table as shown in table 5-4 and fill in all known values.

Start by entering the largest pipe available, DP, into the table. Subtract DP from total fill, FT, to get fill critical,

PC. FC represents the actual cover over the pipe at the critical section. Compare FC to cover required, CR.

To find CR for aircraft, refer to table 5-1, page 5-9, which indicates that an SR-71C aircraft has a culvert weight

type (WT) of 9. The CMP available is 10 gauge. With this information, refer to table 5-2, page 5-10, and select

chart 9, corresponding to culvert WT 9. The diameters and cover are given in chart 9 under the 10-gauge line.

Starting with the largest pipe available, 42-inch or 3.5 feet, CR is 4.0 feet (interpolated between pipe diameters.)

Enter this value in table 5-4. The 42-inch pipe (3.5 feet) cannot be used because its actual cover is 3.01 feet

against a required cover of 4.0 feet. Repeat the process using the next smaller pipe available, 36-inch pipe. It has

a FC of 3.51 feet and a CR of 3.5 feet. This pipe will work.

STEP 5. Determine the culvert capacity and the number of pipes needed (side by side). Use table 5-3, page 5-16,

to find the capacity and velocity for the 36-inch pipe.

Table 5-4. Unsubmerged inlet sample data

The slope of the culvert is 0.5 percent. Entering the graph from the top (pipe diameter), move down the column

until you intersect with the slope in the left-hand column. This will state the quantity of flow in the pipe. The

velocity of flow is shown by following the respective shaded or unshaded areas down and to the left until it ends

in the velocity column, 4 feet per second.

The 36-inch pipe has a capacity of 27.5 cubic feet per second for the 0.5 percent slope. The velocity indicated is 4

feet per second.

STEP 6. Determine the number of pipe required to carry the flow by dividing the total (Q) of 32 cubic feet per

second (Step 1) by the pipe capacity, 27.5 cubic feet per second (Step 5), and

EN5465

5-20

Previous Page

Previous Page