Lesson 2/Leaning Event 1

UW = 147 lb/cu ft

CONTINUOUS MIX PLANT

The amount of materials that are components of the plant mix can be determined best by a

proportionate method. The job mix formula for this method is different. It is best demonstrated

by the following example.

Example: The required tonnage of plant mix for a project is 800 tons. The aggregate blend is

50/40/10 (percentage course aggregate/fine aggregate/mineral filler). The bitumen

content is 6 percent. How many tons of each aggregate are required?

Job mix formula is:

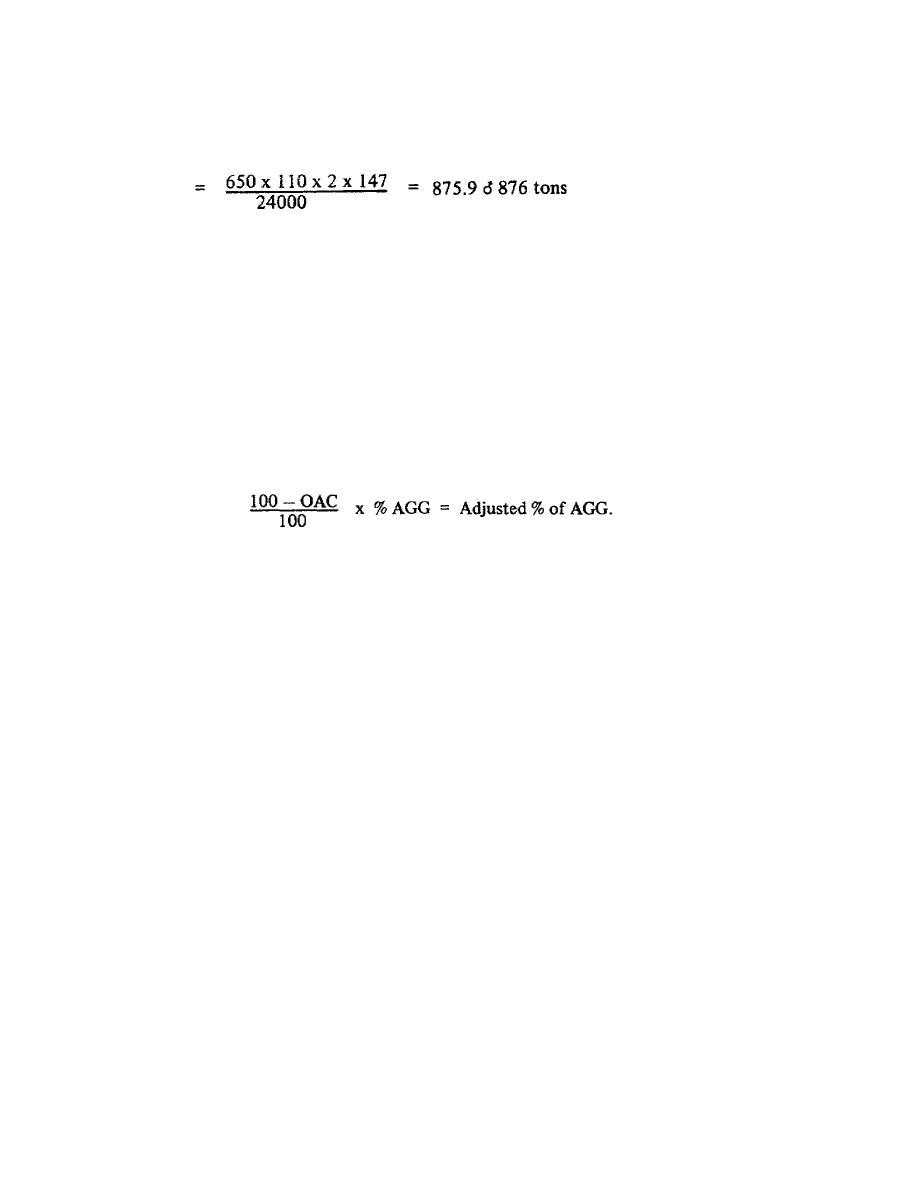

SOLUTION: Total aggregate percent by weight = 100 - 6 = 94 percent, or 0.94.

Coarse/aggregate = 0.94 x 50 percent = 47.0 percent by weight of the total mix.

Fine aggregate = 0.94 x 40 percent = 37.6 percent by weight of the total mix.

Mineral filler = 0.94 x 10 percent = 9.4 by weight of the total mix.

To convert to tons the required tonnage of plant mix is multiplied by the percentage of each

component of the mix. The results should be adjusted so that the sum of the tonnage of

components is equal to the required tonnage of plant mix.

Coarse aggregate:

=

800 x 0.470

=

376.0 tons

Fine aggregate

=

800 x 0.376

=

300.8 tons

Mineral filler

=

800 x 0.094

=

75.2 tons

Bitumen

=

800 x 0.060

=

48.0 tons

800.0

(The bitumen weight was calculated as a check.)

CONSTRUCTION SEQUENCE

The following diagrams illustrate the sequence of operations for priming or tack coating and for

two types of road construction.

24

Previous Page

Previous Page