Lesson 2/Learning Event 1

ROAD MIX (Mixed-in-place Construction)

Road mix or mixed-in-place pavements are commonly constructed in the Theater of Operations.

They may be surface courses, base courses, or subbase courses. As a surface, a road mix is

normally suitable for medium or light traffic.

The principal advantage of mixing-in-place is that it uses aggregate already on the roadbed or

airfield, or that which is available from nearby sources. Aggregates and asphalt can be mixed in

place quickly with a minimum of equipment. However, central plant mixing (if mixing plants

are available) gives better control, often at no increase in effort or time. Some features of mixed-

in-place construction are:

fair control of the moisture and volatile content through aeration with road-mixing

equipment

uniform coating and fair distribution of the asphalt on all aggregate surfaces.

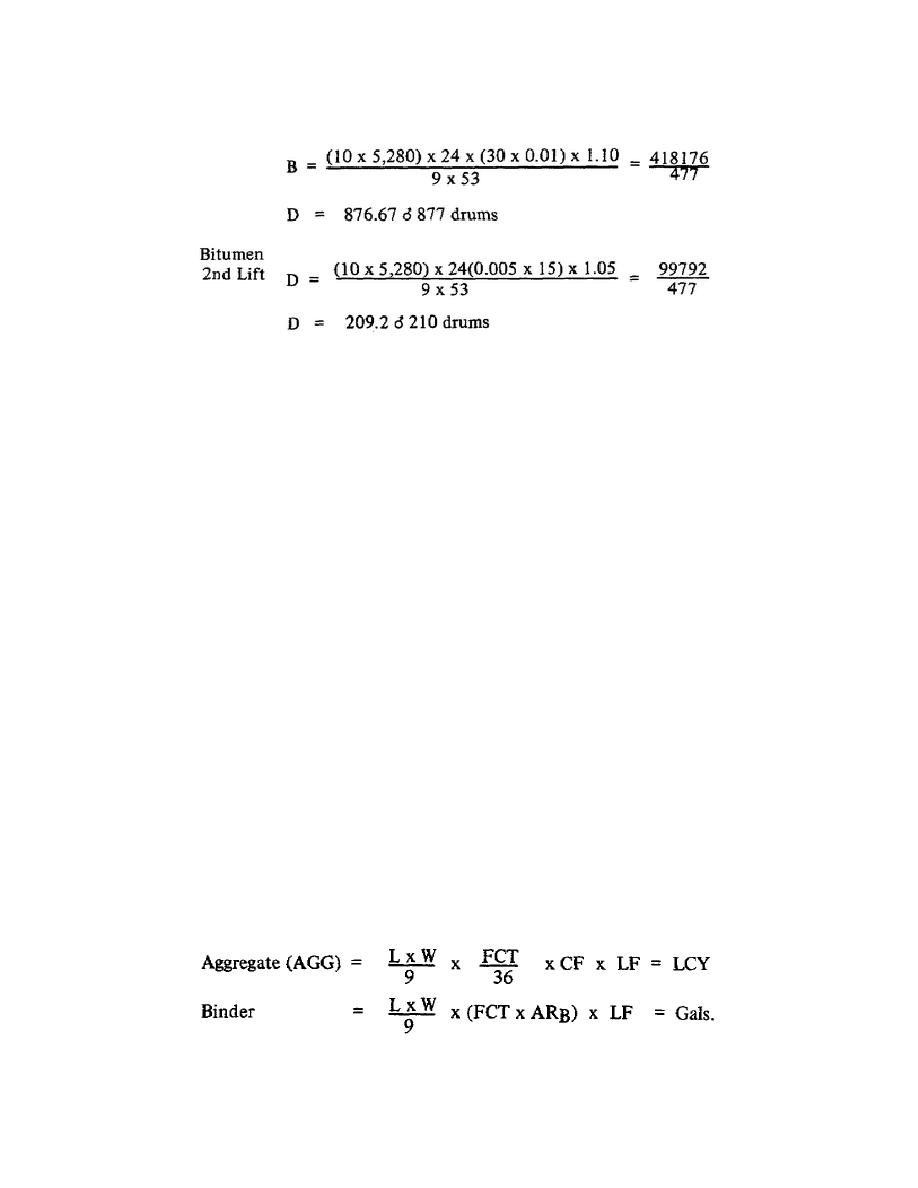

Estimation for Road Mix

Estimates of aggregates required for road mix are identical to requirements for penetration of

macadam pavement. The Modified Marshall Method should be employed for determining the

amount of bitumen required. On the basis of experience, approximately 0.5 gallon per square

yard of bitumen is required for each compacted inch of pavement. If a 1-inch finished pavement

is to be placed, 0.5 gal/sq yd is the approximate rate of application for the bitumen. (The rate of

application is based on the use of open-grade aggregate with a 1-inch maximum particle size.)

The formulas for a road-mix estimation are:

21

Previous Page

Previous Page