Lesson 5/Learning Event

USING THE TORQUE WRENCH

To use a torque wrench, set the specification on the micrometer handle or

note the specification on the scale or dial. Attach the proper socket to

the torque wrench. Place the socket on the nut or bolt to be tightened.

If an assembly containing many bolts or nuts is to be torqued, it is good

practice to use the following three-step procedure:

1. First, torque

all

the

bolts

to

about

three-quarters

of

the

specification.

2. Recheck the specification and the torque wrench setting.

Then,

apply the specified torque to each bolt.

3. Finally, retorque all bolts to the specification, to be sure that

none were missed in the final torquing.

Use a smooth, steady pulling motion with a torque wrench. A fast or a jerky

motion will cause the fastener to be tightened to an incorrect torque. Be

sure to follow the torque specification for each fastener.

Look for

footnotes, in the specification charts, that indicate whether the threads

are to be dry or lubricated with an antiseize compound.

When you are

tightening parts such as cylinder heads or intake manifolds, always find and

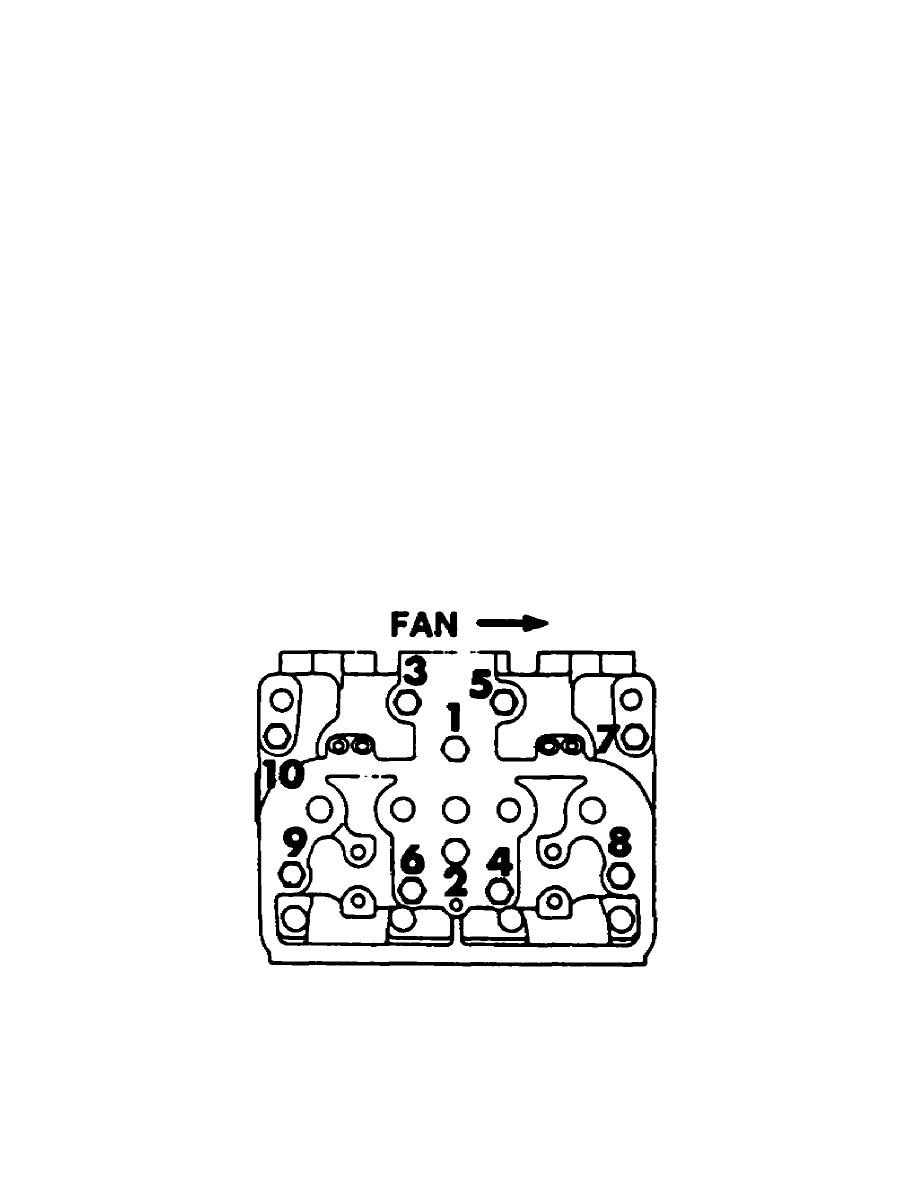

follow the recommended bolt tightening pattern, Figure 66.

FIGURE 66.

MW24 B CYLINDER HEAD BOLT TORQUE SEQUENCE

86

Previous Page

Previous Page