Lesson 5/Learning Event

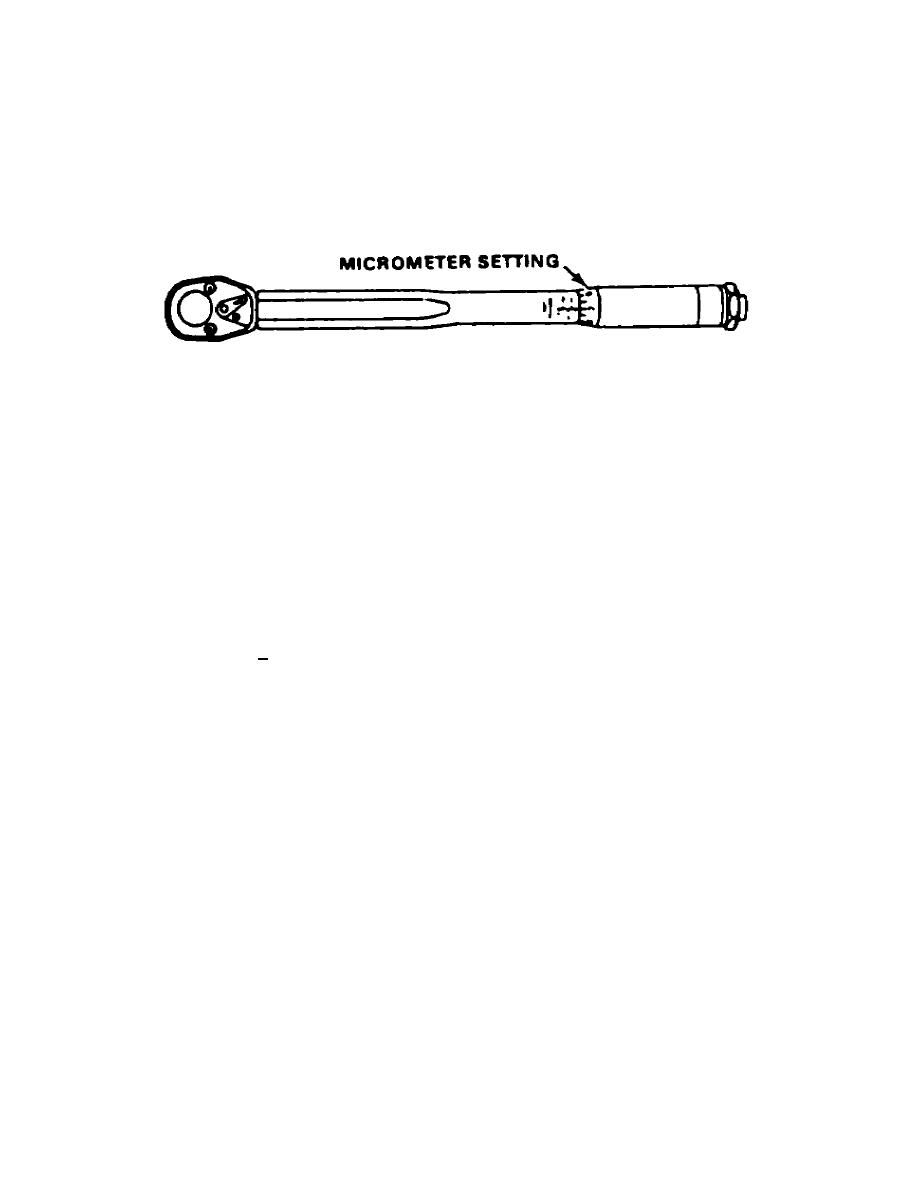

Micrometer or Clicker

The micrometer-type torque wrench, Figure 65, has a built-in micrometer at

the end of the handle where a specified torque can be set by turning the

handle. When the specified torque is reached, a loud click is heard. This

type torque wrench permits very accurate tightening of nuts and bolts.

FIGURE 65.

MICROMETER TORQUE WRENCH

Regardless of their type, most torque wrenches measure torque in foot-pounds

(ft-lb). However, some torque wrenches (mainly those used for more accurate

readings on smaller nuts and bolts) measure torque in inch-pounds (in-lb).

Twelve inch-pounds equal 1 foot-pound.

To convert foot-pounds to inch-

pounds, multiply the foot-pound by 12.

To convert inch-pounds to foot-

pounds, divide the inch-pounds by 12.

Example of converting foot-pounds to inch-pounds:

75 foot-pounds x 12 inch-pounds = 900 inch-pounds.

Example of converting inch-pounds to foot-pounds:

1,260 inch-pounds 12 inch-pounds = 105 foot-pounds.

Torque wrenches are issued in several sizes; they may have a 1/4-, 1/2-, or

3/4-inch square drive to receive socket wrenches, and the capacity may range

up to 600 foot-pounds.

SELECTING A TORQUE WRENCH FOR A SPECIFIC JOB

Before selecting a torque wrench for a job, note the torque specification.

Then select and use a torque wrench that will read about midrange for the

specified torque. For example, a typical 1/2-inch drive micrometer torque

wrench measures from 30 to 200 foot-pounds.

It would be the best torque

wrench for a job requiring about 100 foot-pounds of torque.

Typically, a

3/8-inch-drive torque wrench reads from 15 to 100 foot-pounds. A 1/4-inch-

drive torque wrench measures from 30 to 300 inch-pounds.

85

Previous Page

Previous Page