Lesson 1/Learning Event 2

On larger work, it is often necessary to have the work stationary and

positioned to permit access to the micrometer. Figure 11, Part B, shows the

proper method of holding a micrometer when checking a part too large to be

held in one hand.

The frame is held by one hand to position it and to

locate it square to the measured surface.

The other hand operates the

thimble either directly or through the ratchet. You should check large flat

parts in several places to determine the amount of variation.

To gage a shaft, Figure 11, Part C, hold the frame in one hand while

operating the thimble with the other. In measuring a cylindrical part with

a micrometer, it is necessary to "feel" the setting to be sure that the

spindle is on the diameter. You must check the diameter in several places

to determine the amount of out-of-roundness.

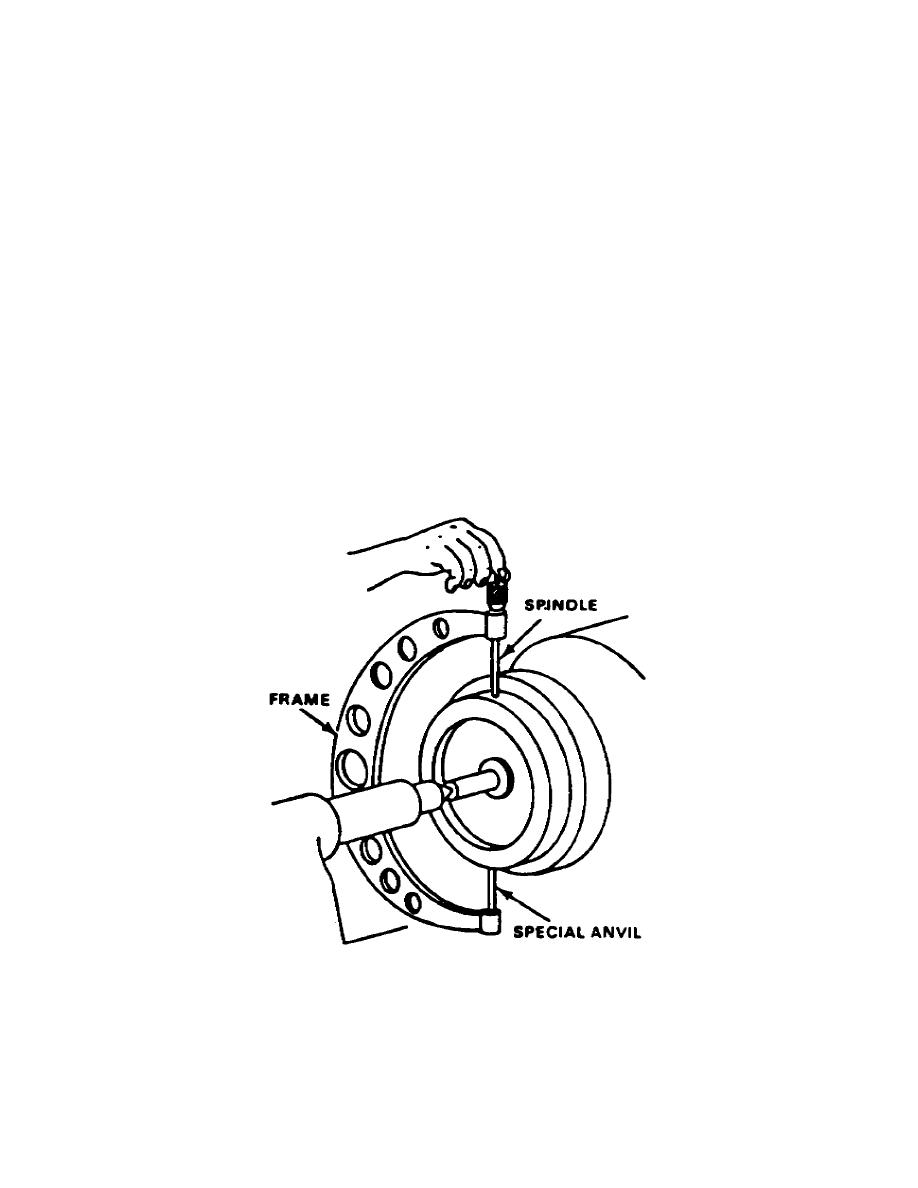

Micrometer calipers are made in various sizes up to 168 inches. Figure 12

shows a pulley being checked with a micrometer whose range has been reduced

by a special anvil screwed into the frame. A set of different length anvils

permits this micrometer to be used over a wide range of sizes.

Yet, the

spindle only moves 1 inch. This micrometer has been lightened in weight by

its I-section construction and by boring holes in the frame.

FIGURE 12.

CHECKING DIAMETER OF A PULLEY

15

Previous Page

Previous Page