b. Wood Screws. Wood screws are made of iron, bronze, brass,

copper, or other metals; however, some are coated with nickel or

chrome to match specialfinish hardware. The main types of wood

screws are roundhead, oval head, and flathead, which can be either

slotted or Phillips head.

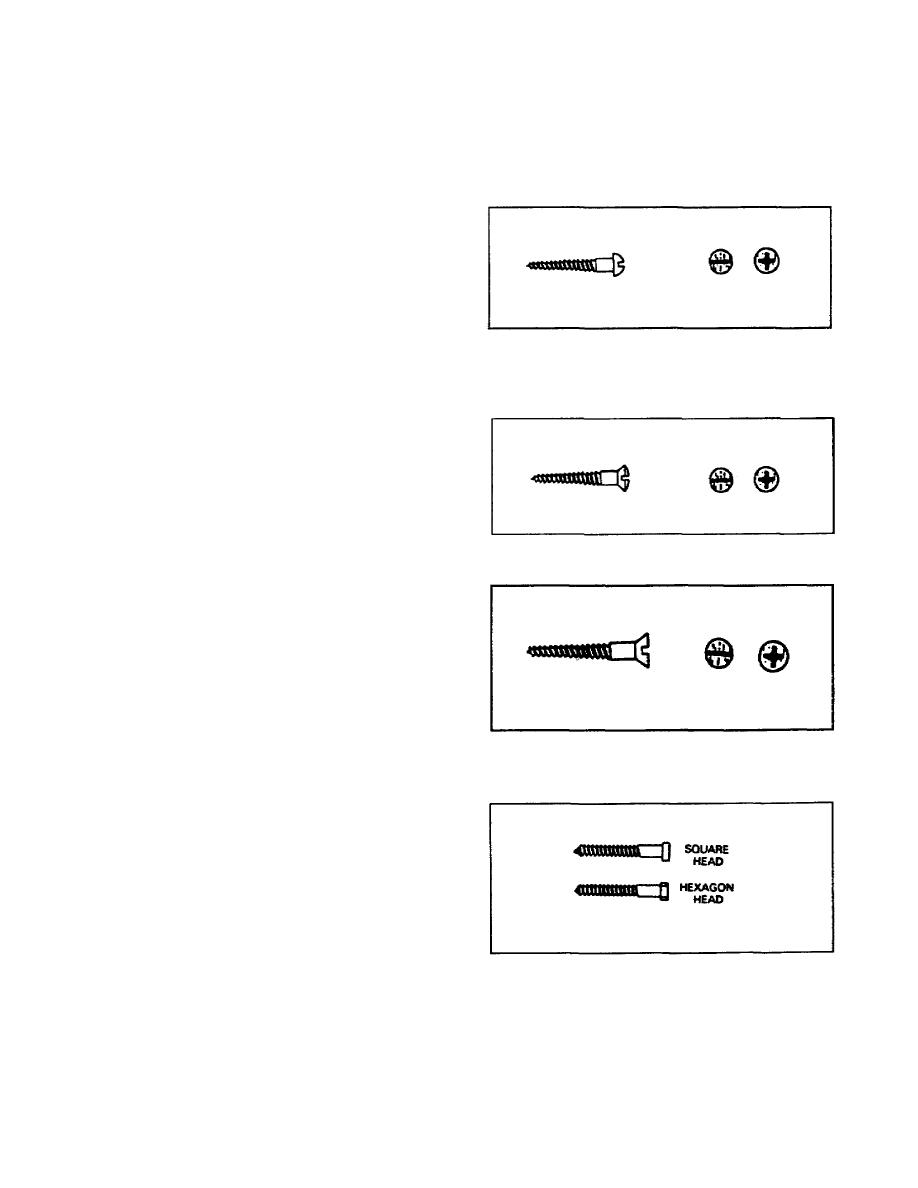

(1) Roundhead

Screws.

Roundhead screws (Figure 134)

are usually used on a surface

where the heads will show. The

head is not countersunk, and for

this reason it should have a

pleasing finisheither blued or

polished. If slottedhead, the

Figure 1-34.

Roundhead screw

screw slot should always be left

in a parallel position to the

grain of the wood.

(2) Ovalhead

Screws.

Ovalhead screws (Figure 135)

are used to fasten hinges or

other finish hardware to wood.

If slottedhead, the screw slots

of these screws should be

parallel to each other for

Figure 1-35.

Ovalhead screw

better appearance.

(3) Flathead

Screws.

Flathead screws (Figure 136)

are used where the head will not

show. The head should be

countersunk until it is level

with or slightly below the

finished surface. If flathead

screws are used on an exposed

area, they should be countersunk

Figure 1-36.

Flathead screw

in a hole that can be plugged.

(4) Other Screws.

(a) Lag Screws. Lag

screws are longer and heavier

than the common wood screw and

have coarser threads. They have

square and hexagon heads (Figure

137). They are used when

ordinary wood screws would be

too short or too light and

spikes would not be strong

Figure 1-37.

Lag screws

enough.

1-35

EN5155

Previous Page

Previous Page