15. Connect a headloss of 5 feet per 1,000 feet of pipe with 7-inch diameter pipe

in columns three and two respectively of figure 14, attached memorandum.

The

intersection of this line with column one gives a flow of 270 gpm.

16. If the maximum allowable headloss is 10 feet of water in 500 feet of pipe,

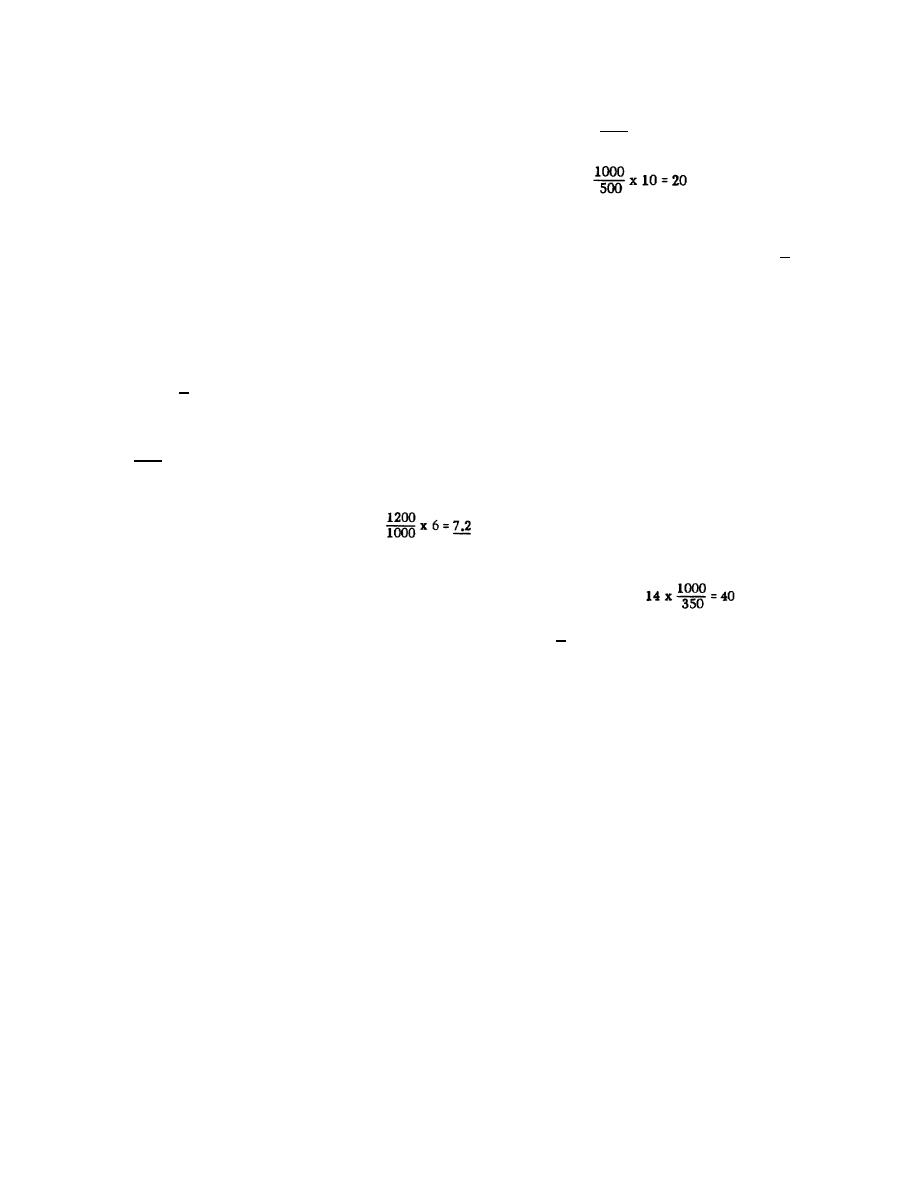

the maximum allowable headloss per 1,000 feet of pipe is

feet of water

per 1,000 feet. Connect 100 gpm n the left column of figure 14 with 20 feet per

1,000 feet in the third column. This line intersects the second column at a value

of 3.6 inches.

Hence, a 3.6-inch diameter is the minimum that will allow the

required flow while keeping the headloss below 10 feet of water. Therefore, 4-inch

diameter pipe is required, the next larger size.

17. Since the coefficient of friction is other than 100, figure 15 must be used.

Connect the point in the left column corresponding to a flow coefficient of 150 to

a 5-foot per 1,000 foot headloss in the second column, and extend this line until

it intersects the pivot line.

Connect this point on the pivot line with a

discharge of 70 gpm, and read the minimum required pipe diameter as 3.6 inches.

Therefore, 4-inch pipe is required.

18. As shown by figure 17, the main from C to D must be able to furnish the peak

demand for buildings 3, 4, 5, and 6. Hence, it must be able to carry 65 + 45 + 30

+ 60= 200 gpm.

19. For a flow of 200 gpm and a pipe size of 6 inches, figure 14 gives the

headloss as 6 feet per 1,000 feet of pipe. Since the section in question is 1,200

feet long, the actual headloss is

feet.

20. The total headloss allowed is 25 feet.

However, 11 feet have already been

used up in the main. Hence you have 25 - 11 = 14 feet left for the branch line.

The branch is 350 feet long, so the headloss in the branch is

feet

per

1,000 feet. From figure 14, for a loss of 40 feet per 1,000 feet and a flow of 70

gpm, the required diameter is 2.7 inches, so specify 3-inch pipe.

3-3

Previous Page

Previous Page