Lesson 2/Learning Event 7

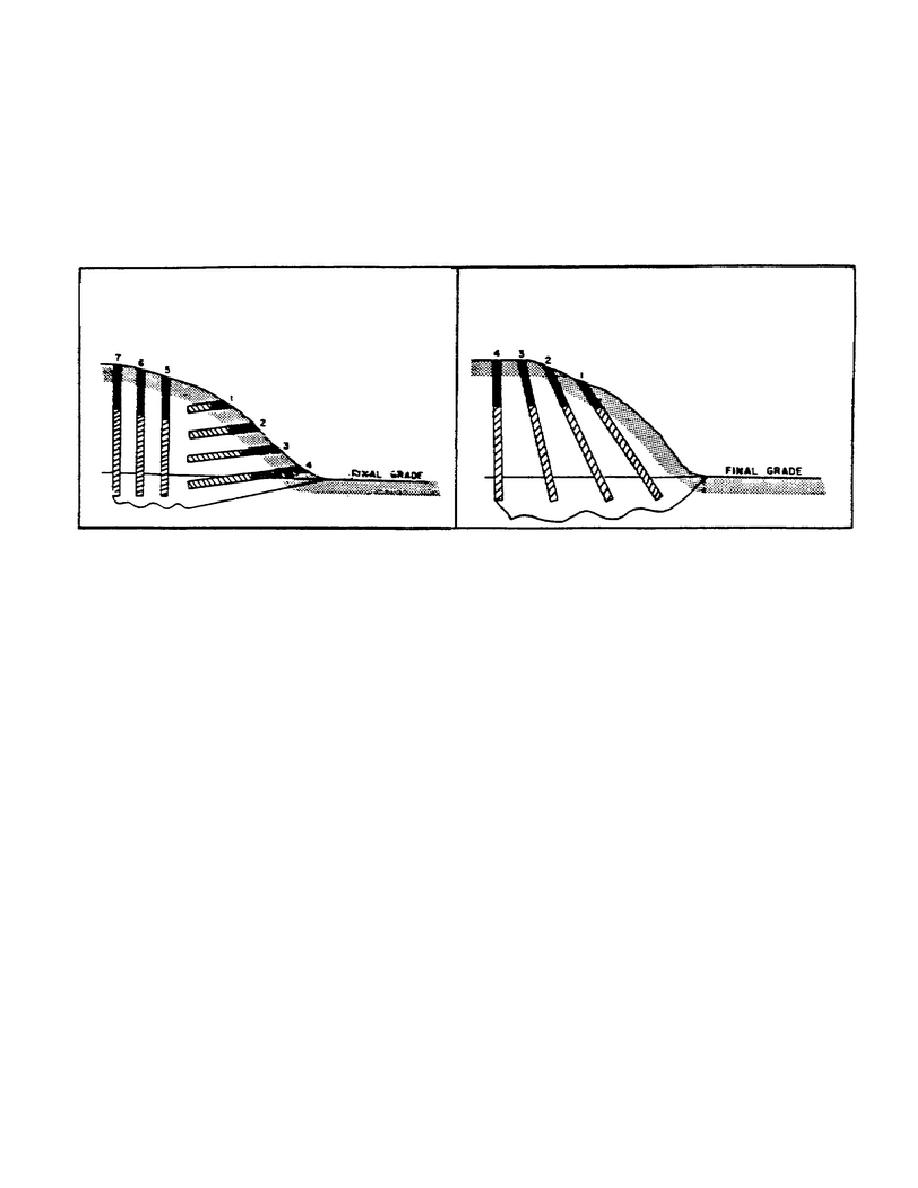

Toe Cuts. Unless the rock in a hillside or terrain quarry has a vertical face, you will have to remove a

toe of rock to begin quarrying. This will require the use of different types of holes, shown in Figures 7

and 8. The method shown in Figure 7 usually gives better control over rock fragmentation and

displacement and is preferred. However, the method shown in Figure 8 involves fewer setups. All

vertical, steeply-inclined, and lifter holes should be subdrilled from 1 to 3 feet (0.3 to 0.9 meters) below

the final grade to assure that the rock between holes will be broken to the desired grade line.

FIGURE 8.

ESTABLISHING

A

FIGURE 7.

TOE

REMOVAL

BY

VERTICAL FACE USING

HORIZONTAL

AND

INCLINED AND VERTICAL

VERTICAL BLASTHOLES

BLASTHOLES.

Ramp Cuts. Figure 9 shows a suggested pattern for excavating a ramp down into a subsurface quarry.

A vertical face is established in the first blast. Use of this method will allow the easiest possible loading

of blasted rock. An alternate method is to establish a vertical face near the low end of the ramp using a

V-cut or pyramid cut. Blasting may then proceed simultaneously up and down the ramp. The blasts at

the lower end after the first V- or pyramid cut will normally be directed into the broken rock produced

by previous blasts. Another method is to use a standard, full-depth vertical or steeply-inclined blast

pattern to fragment the rock under the planned ramp to the level of the quarry floor. A power shovel or

dozer may then construct its own ramp down into the pit. This allows for continuity in drilling and

blasting operations. The resulting ramp car also be removed easily, should this be desired.

44

Previous Page

Previous Page