Lesson l/Learning Event 2

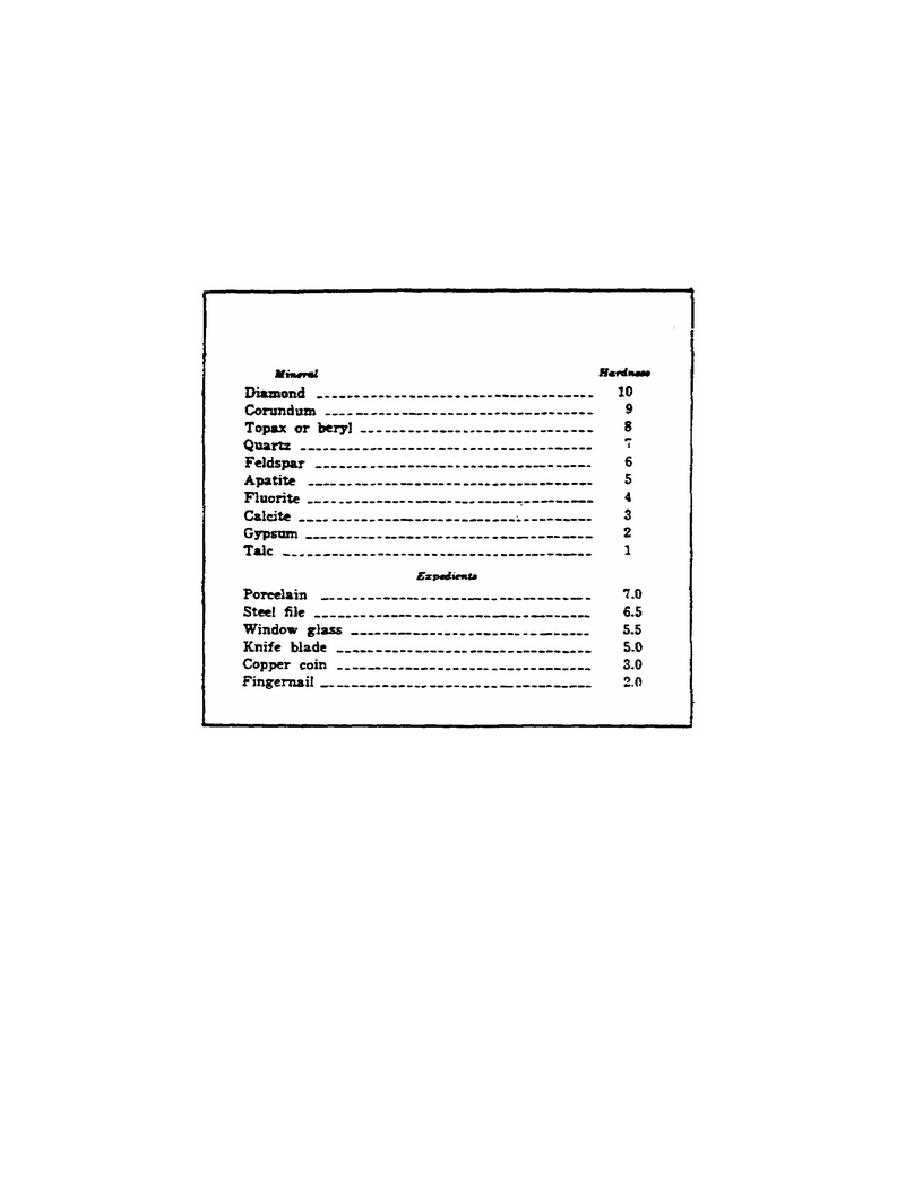

Hardness is a rock's resistance to scratching or abrasion. This property is important in determining the

suitability of aggregate for construction. Usually hardness is measured using Moh's scale shown in

Table 2. The harder the material, the higher its number on the Moh scale. Any material will scratch

another of equal or lesser hardness. In the field, hardness may be measured using the common

expedients shown in Table 2. For example, if you are able to scratch a rock with a knife blade, the rock

must have a hardness of 5.0 or less. A rock which can be scratched by a copper coin has a hardness of

3.0 or less.

TABLE 2. MOH'S SCALE OF HARDNESS

Aggregates for general construction should have a hardness of 5 to 7. In other words, they should be

difficult or impossible to scratch with a knife. Materials with a hardness greater than 7 should be

avoided since they cause excessive wear to crushers, screens, and drilling equipment. Materials with a

hardness less than 5 may be used if other sources of aggregate prove uneconomical.

The requirements as to toughness, durability, crushed shape, and other properties vary according to the

type of construction. The shorter life spans required in the theater of operations permit a wider choice of

materials than would otherwise be acceptable.

Remember that chemical stability has specific importance when considering aggregates for concrete.

Several rock types contain impure forms of silica which react with alkalies in cement. This reaction

forms a gel which absorbs water and expands to crack or disintegrate hardened concrete. These reactive

10

Previous Page

Previous Page