TM 58113/AFM 88-9, Chap. 3

CHAPTER 3

STATIC ELECTRICITY PROTECTION

31. Discussion

this case. Moreover, if a piece of plastic is merely

pressed--not rubbed-against a metal plate and

a. General. While the practice of grounding electri-

taken away, it will have a charge where actual con-

cal systems is well established, the full implications

tact was made. Whereas if the plastic is rubbed on

of static electricity protection are not always under-

stood. The object of static electricity protection is to

the metal, the charges will be increased in proportion

to the number of little areas which actually make con-

provide a means whereby static electricity charges,

tact. The plastic, being a nonconductor, tends to re-

separated by whatever cause, may recombine harm-

tain that state at any little area of contact. When an

lessly before sparking charges are attained. In order

insulating solid becomes charged, the charge tends to

for a static electricity charge to become a source of

remain anchored to the area where it was developed.

trouble, the following conditions must be considered:

Good insulators having clean dry surfaces in low at-

(1) There must be a means of static generation.

mospheric humidity can hold their charge for quite a

(2) There must be a means of accumulation of a

while. A poor insulator quickly loses its charges to

static charge capable of producing ignition.

surrounding areas, and a good insulator having sur-

(3) There must be a means of spark discharge of

face contamination will become somewhat conductive

the accumulated charge.

regardless of humidity, and will permit leakage to

(4) There must be an ignitable mixture or atmos-

phere at location of spark discharge to constitute an

take place. A volume of relatively dry space which is

normally a good insulator containing neutral mole-

explosive or fire hazard.

cules can also become charged by radioactivity andl

(5) The static potential must be maintained to

constitute a hazard to personnel.

cosmic rays. However, since there are no known per-

fect insulators, isolated charges of static electricity

(6) The static charge must be continuously con-

always eventually leak away. The problem is to pro-

ducted to constitute a compromise of classified com-

vide instant control of hazardous accumulations of

munications. It may be impracticable to attempt miti-

static charges without reliance upon natural bleeding

gation or control of all static charges. Furthermore,

most static charges normally do not accumulate suffi-

or leaking away of such charges. For static electricity

to discharge as a spark, the accumulated charge must

cient charge to supply enough energy to produce a

be capable of jumping through a spark gap. The mini-

spark capable of causing ignition. It should be recog-

mum sparking voltage at sea level is generally ac-

nized, however, that when static electricity accumu-

lates, it becomes a potential hazard, and therefore

cepted as approximately 350 volts for the shortest

must be controlled as required. Electrostatic electric-

measurable length of gap. Characteristics of the gap

are also a limiting factor. For discharge to constitute

ity charges are generated by friction or contact be-

tween dissimilar conductive, semiconductive or

a fire hazard, the gap must exceed a critical minimum

length to permit the buildup of a sufficient energy

nonconductive moving objects, materials, liquids or

level for an incendiary spark to result. Of course,

air particles. Obviously, we live in an electrostatic

there must be an ignitable mixture in the gap where

environment containing constant movement of mole-

the spark occurs. This energy level is estimated to be

cules, none of which is inherently grounded. When

in order of 10-8 joules minimum. An example of

two solids move into contact, a voltage difference or

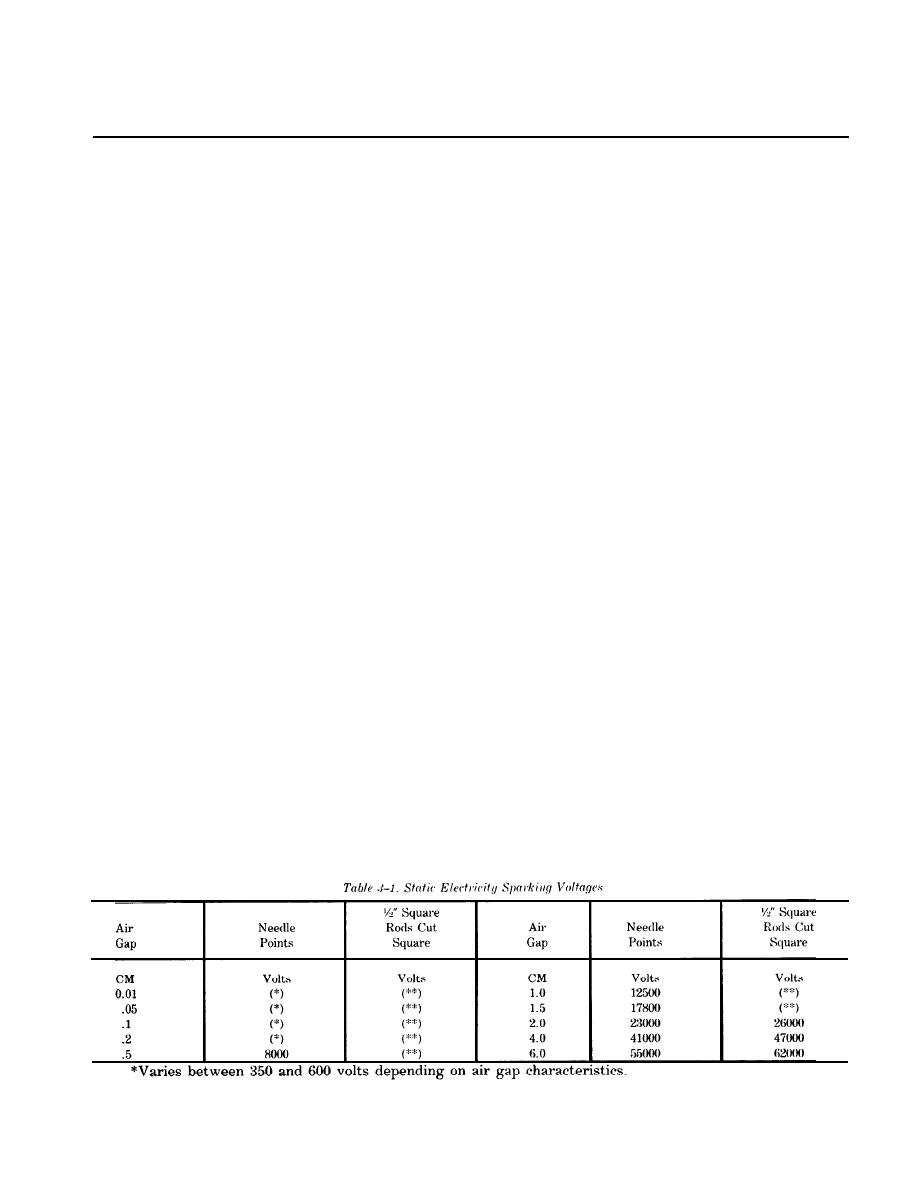

sparking voltages required to break clown various air

contact charge occurs. In most cases it is very small,

gap spacings is furnished in table 31. For calculating

but with tin and iron, as specific examples, it is

ignition energy, refer to NFPA No. 77.

nearly a third of a volt. The tin is electropositive in

**Varies between 450 and 22,000 volts depending on air gap characteristics.

3-1

Previous Page

Previous Page