TM

5-811-1/AFJMAN

32-1080

c. Cable ampacity. The current carrying capaci-

ing cables. Calculations of the position effect indi-

ties of cable will be in accordance with ampacities

cate that, to equalize operating temperatures, full-

given in the NEC and IEEE/ICEA publications.

load ratings of cables appropriate for isolated

There are many factors taken into account in

(one-way) ducts should be decreased for multiple

duct banks. For example, in an eight-way-duct

determining these allowable ampacities such as

bank the recommended full-load percentage de-

operating temperatures, soil effects, shielding

losses, and conductor configurations, but the vari-

crease for each corner duct is 95 percent and for

each interior duct is 83 percent giving an average

ables which cause the most concern are circuit

loading and location in a duct bank. Because of

load percentage decrease of 89 percent. This derat-

load diversity, peak demands for cables in a duct

ing still allows provision for loads in excess of the

bank will not occur concurrently in most cases.

normal feeder capacity usually found on military

installations, as the summation of feeder capaci-

This diversity factor will be taken into account

when computating expected heat build-up in a

ties is generally from three to eight times the

duct bank. Heat dissipation from a cable is also

overall capacity of a main electric supply station.

d. Power cable joints. A splice which connects

influenced by the position occupied by the cable in

cables rated 2.5 kV and above is known as a power

a duck bank. Cables in duck bank corners dissi-

pate heat more effectively than cables in interior

cable joint. Cable joints are composed of connectors

ducts, because of the greater soil dissipating area

to join two or more cables for the purpose of

and the smaller heat contribution from neighbor-

providing a continuous electric path plus necessary

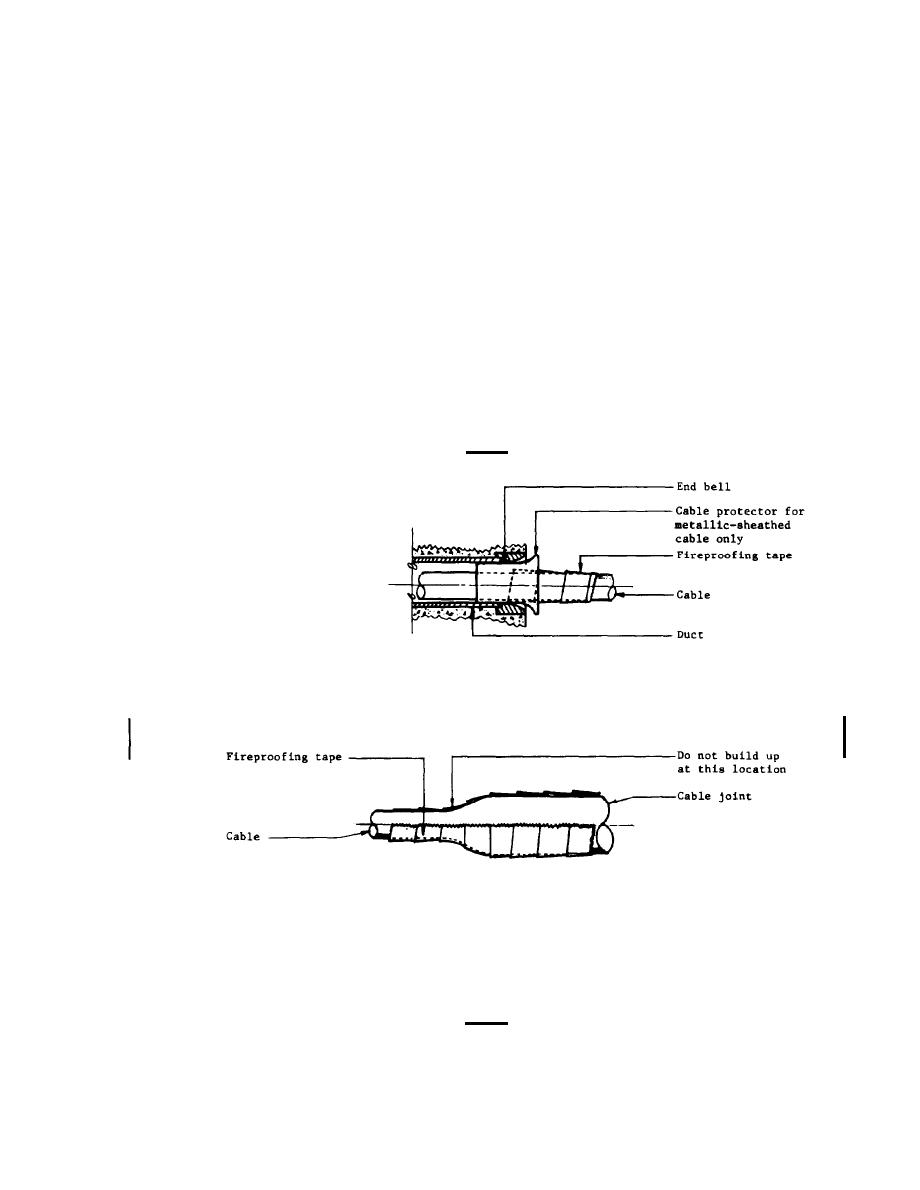

DUCT ENTRANCE

CABLE JOINT

REQUIREMENTS

Fireproof only medium-voltage circuits (over 600-volts).

Fireproof cables their entire length within

the manhole and Into the duct entrance as indicated.

US Army Corps of Engineers

Table 7-1. Rated Conductor Temperatures.

7-3

Previous Page

Previous Page