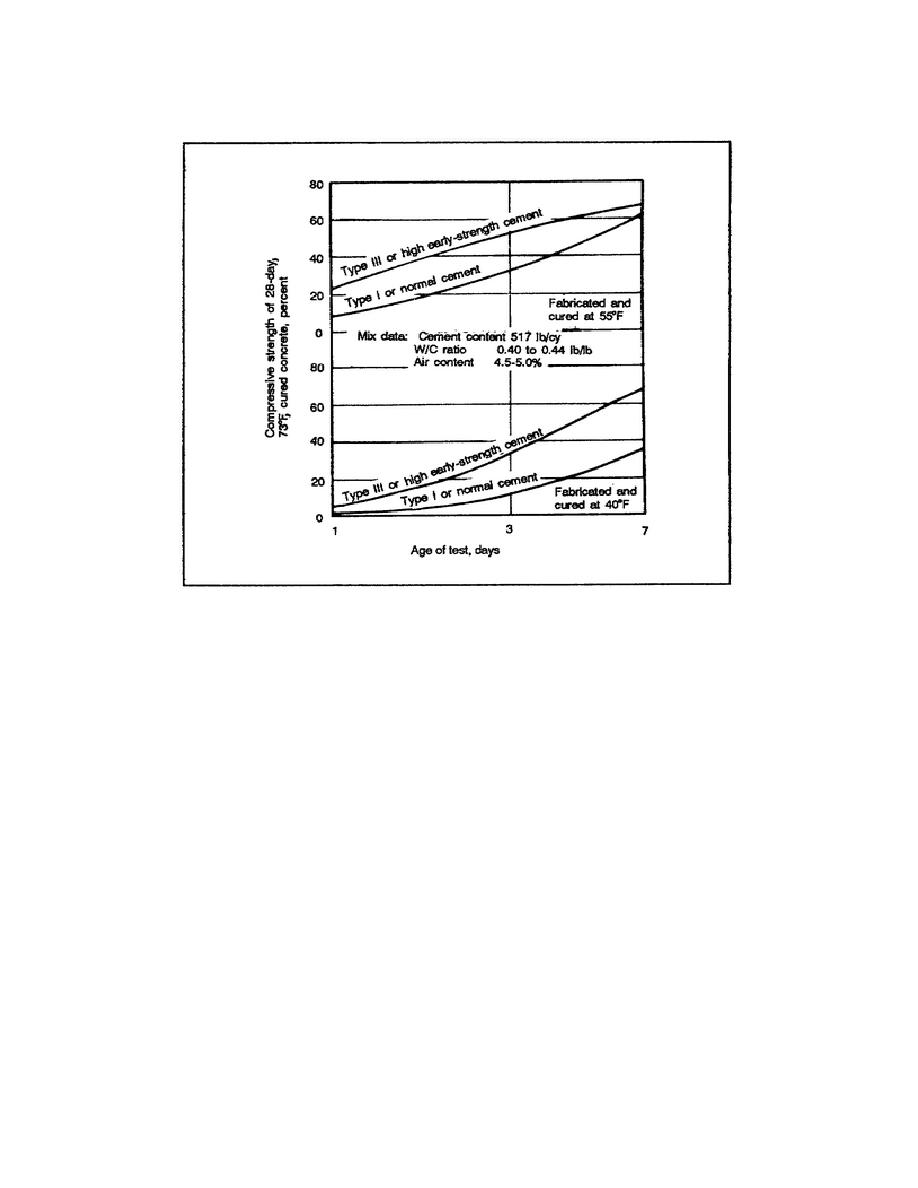

Figure 4-17 shows that the early strengths achieved by Type III or higher early-strength cement are higher than

those achieved by Type I cement.

Figure 4-17. Relationships between early compressive strengths of

portland cement types and low curing temperatures.

COLD-WEATHER TECHNIQUES

Heating Concrete Ingredients

Thawing frozen aggregate makes proper batching easier and avoids pockets of aggregate in the concrete after

placement. If you thaw aggregate in the mixer, check for too much water content. You seldom need to heat

aggregate in temperatures above freezing. But at temperatures below freezing, you can produce concrete having

the required temperature by heating the fine-aggregate only.

Heating aggregate. You can use any of several methods to heat aggregate. One for small jobs is to pile it

over metal pipes containing fires. The average temperature of the aggregate should not exceed 1500F.

Or, you can stockpile aggregate over circulating steam pipes. Cover the stockpiles with tarpaulins to

retain and distribute the heat. You can also inject live steam directly into a pile of aggregate, but the

resulting variable in moisture content can cause problems in controlling the amount of mixing water.

Heating water.

Mixing water is easier to heat because it can store five times as

much heat as solid materials having the same weight, although aggregate and cement

weigh much more than water. You can use the water's stored heat to heat other concrete

EN5466

4-28

Previous Page

Previous Page