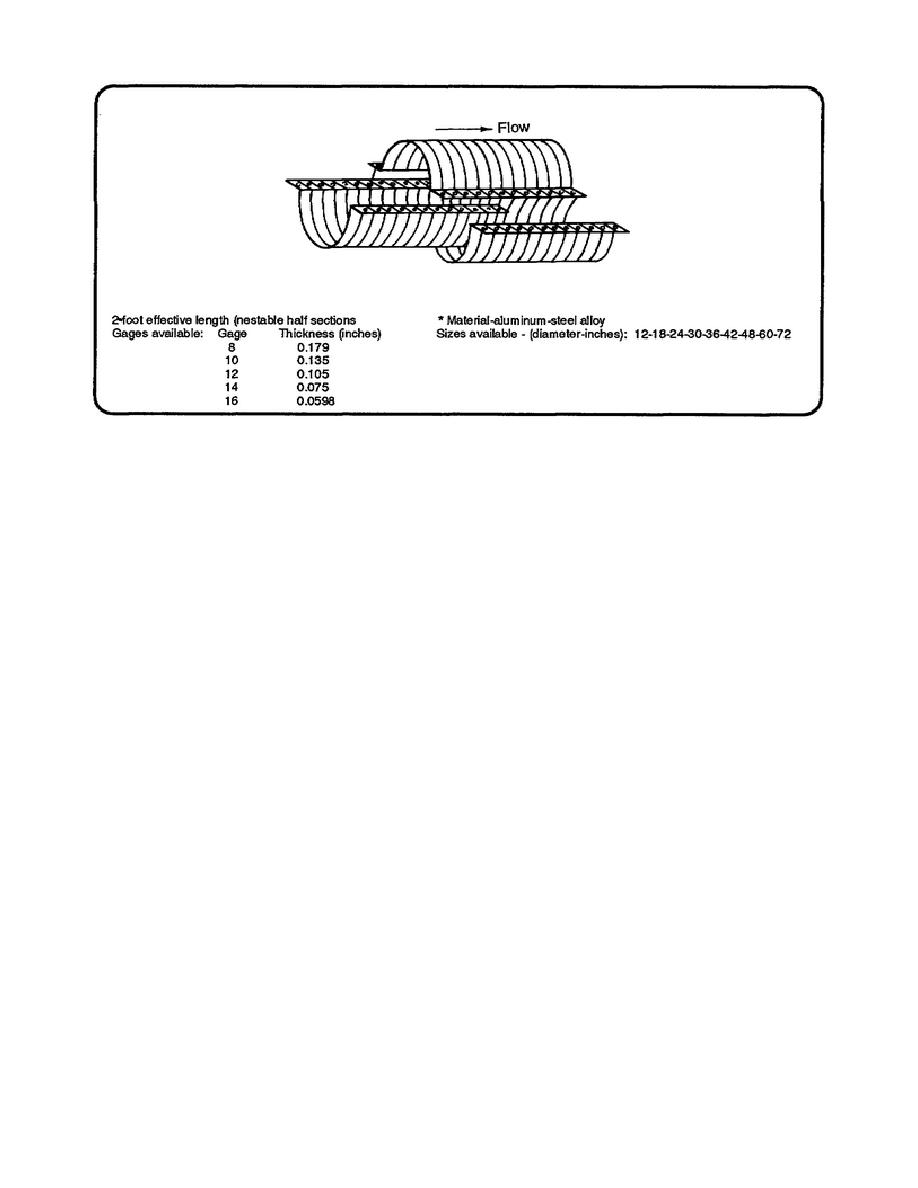

Figure 5-2. Nestable type CMP

Second, if the soil of the fill has excessive fines, all joints should be sealed with tar or asphalt. This will

prevent the fine material being carried into the pipe by seepage flowing in the fill. If this action is not

taken, large voids can be created that will cause the fill to collapse.

CONCRETE PIPE

Consider using concrete pipe when it is available. Concrete pipe has three advantages over CMP. First, it is

stronger, and therefore requires less cover than CMP to support the same load. Second, the interior surface is

smoother (Manning's "n" = 0.013). This means that a concrete pipe, the same diameter and set on the same slope

as one of corrugated metal, will carry a higher Q. Third, concrete pipes are easily made and are more readily

available in remote areas. There are two factors to keep in mind when constructing concrete pipe culverts.

Concrete pipes require headwalls both upstream and downstream to prevent the pipe sections from

separating. A supporting bench or cradle may be used in lieu of the downstream headwall.

All the joints between the pipes should be sealed with a bituminous material or grout to prevent seepage

into and out of the pipe.

CONCRETE BOX

Concrete box culverts have good hydraulic capacity and therefore can be considered for use where it is necessary

to utilize the full area of the waterway. Additionally, they can be designed to withstand external loads with little

or no cover. They are especially adaptable to culvert sites in rock cuts where bedding may be a problem

restricting the use of other types of culverts. One possible disadvantage is that the design of concrete boxes

requires a knowledge of reinforced concrete design. The construction requires close supervision because the

concrete form work, the placement of the reinforcing steel, and the concrete mix itself is critical.

EN5465

5-4

Previous Page

Previous Page