Lesson 4/Learning Event 1

able when one considers that the plant should run continuously in order to produce high quality

pavement. The paver can only place the mix as fast as deliveries are made to it. It should not

stop and start in order to make high quality plant mix pavement. Therefore, the output of the

plant, laydown rate of the paver, and truck delivery rate should all be matched.

This concept is somewhat unconventional and not widely practiced in Army paving operations in

the past. If it is applied, however, both production and paving operations will improve

immensely by avoiding starting and stopping the plant during one period of production.

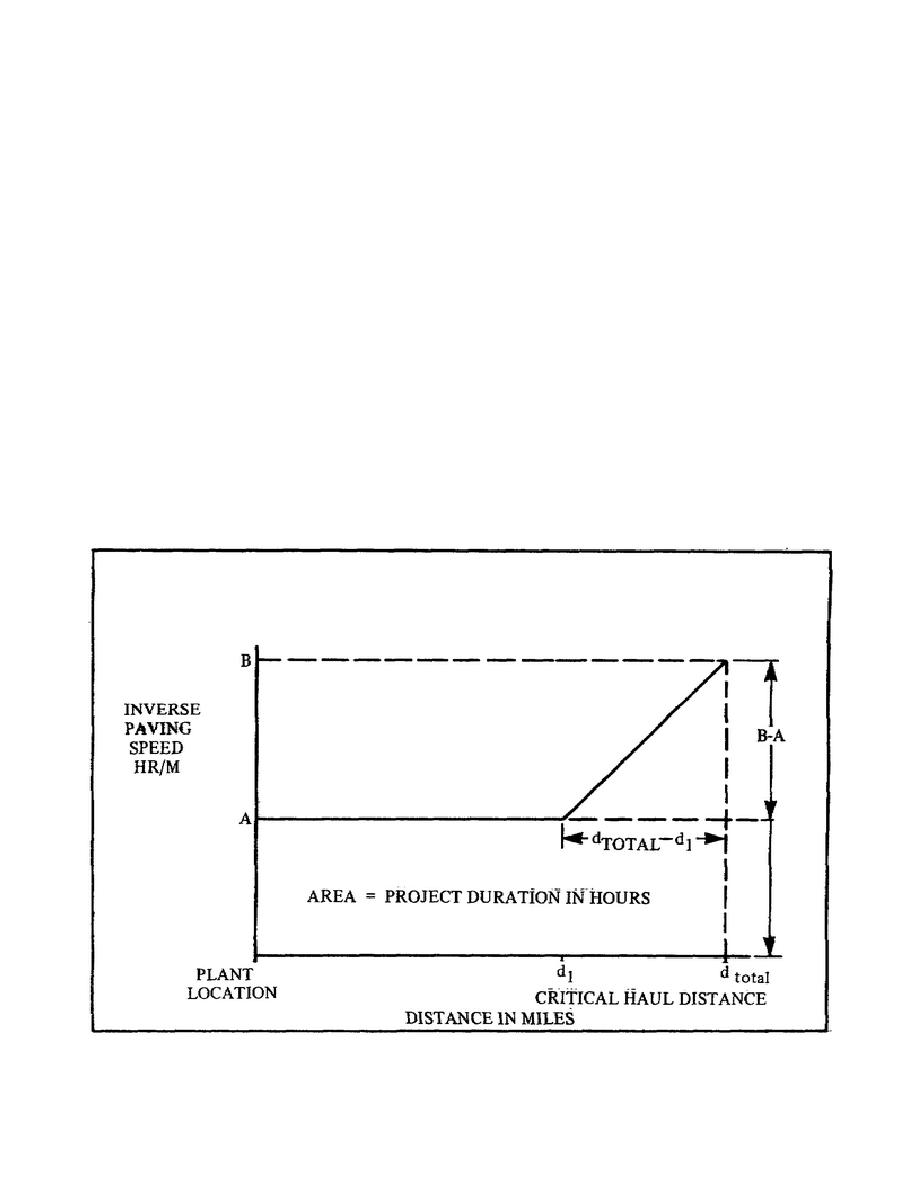

Figure 10 is a graph of the inverse of the paver speed in miles per hour versus the distance the

paver is from the plant. It is assumed that there is a fixed number of trucks hauling plant mix.

Between zero miles and d miles from the plant, the inverse speed remains constant. The trucks

are able to haul plant mix at the maximum plant output. Beyond dl the trucks are not able to haul

at a rate that will keep up with the maximum plant output. Each mile that the paver moves away

from the plant results in a diminished delivery rate to the paver and, consequently, a higher

inverse paver speed in hours per mile. Point A represents the inverse paver speed between the

plant and d miles down the road. Point B represents the inverse paver speed at the end of the

paving project, dtotal (the maximum distance from the

FIGURE 10. PRODUCTION ESTIMATION GRAPH

41

Previous Page

Previous Page