Lesson 1/Learning Event 2

Slow-Curing (SC). Composed of asphalt cement and diesel fuel, with a curing time of 48 to 60

hours.

Road-Oil. A heavy petroleum oil.

Grades of Asphalt Cutbacks

If a great amount of cutterstock is added to a given amount of asphalt cement, a very thin liquid will

result. Different amounts of cutterstock are added to a given amount of asphalt cement (AC) to obtain

various thicknesses or viscosity grades of cutbacks. A new set of specifications for asphalt cutbacks has

been approved by the Corps of Engineers. This specification covers the following types and viscosity

grades (Kinematic Viscosity):

Rapid-Curing (RC) -70,250,800,3000

Medium-Curing (MC) -30,70,250,800,3000

Slow-Curing (SC) - 70, 250, 800, 3000

ASPHALT EMULSIONS

It is often advantageous to use as asphalt material that is liquid at room temperature and yet will not

burn. Asphalt emulsions (emulsified asphalts) possess these properties.

Asphalt emulsions are composed of asphalt cement, water, and an emulsifier mixed together to produce

a liquid material. Asphalt and water will not mix alone so a chemical agent called an "emulsifying

agent" must be added. It is this emulsifying agent that enables the asphalt and water to mix. Common

emulsifying agents are soaps, animal blood, chemicals, and certain specified colloidal clays in dust.

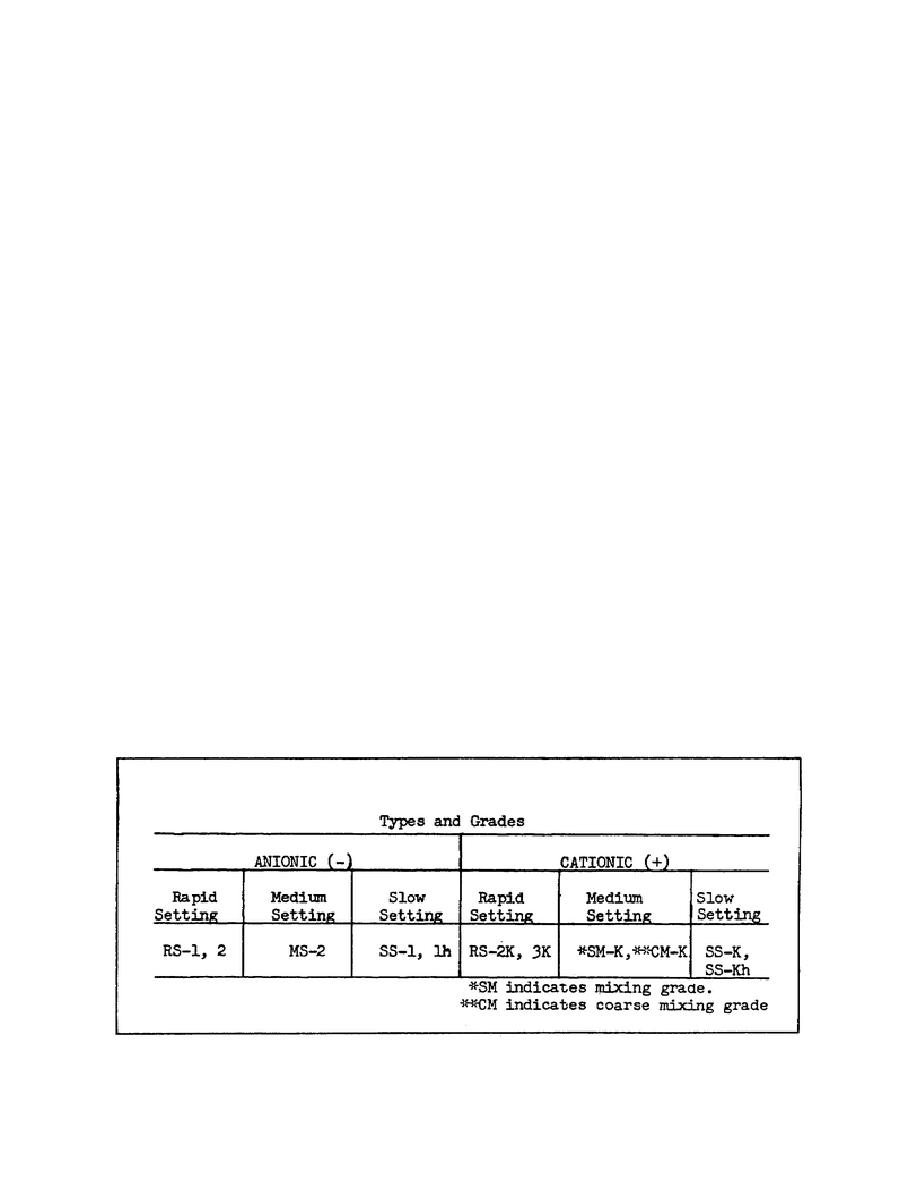

Emulsified asphalts may be of either the anionic electro (negatively) charged asphalt globules, or

cationic electro (positive) charged asphalt globules, depending upon the emulsifying agent.

TABLE 1. TYPES OF ASPHALT EMULSIONS

5

Previous Page

Previous Page