Lesson 1/Learning Event 1

MECHANICS

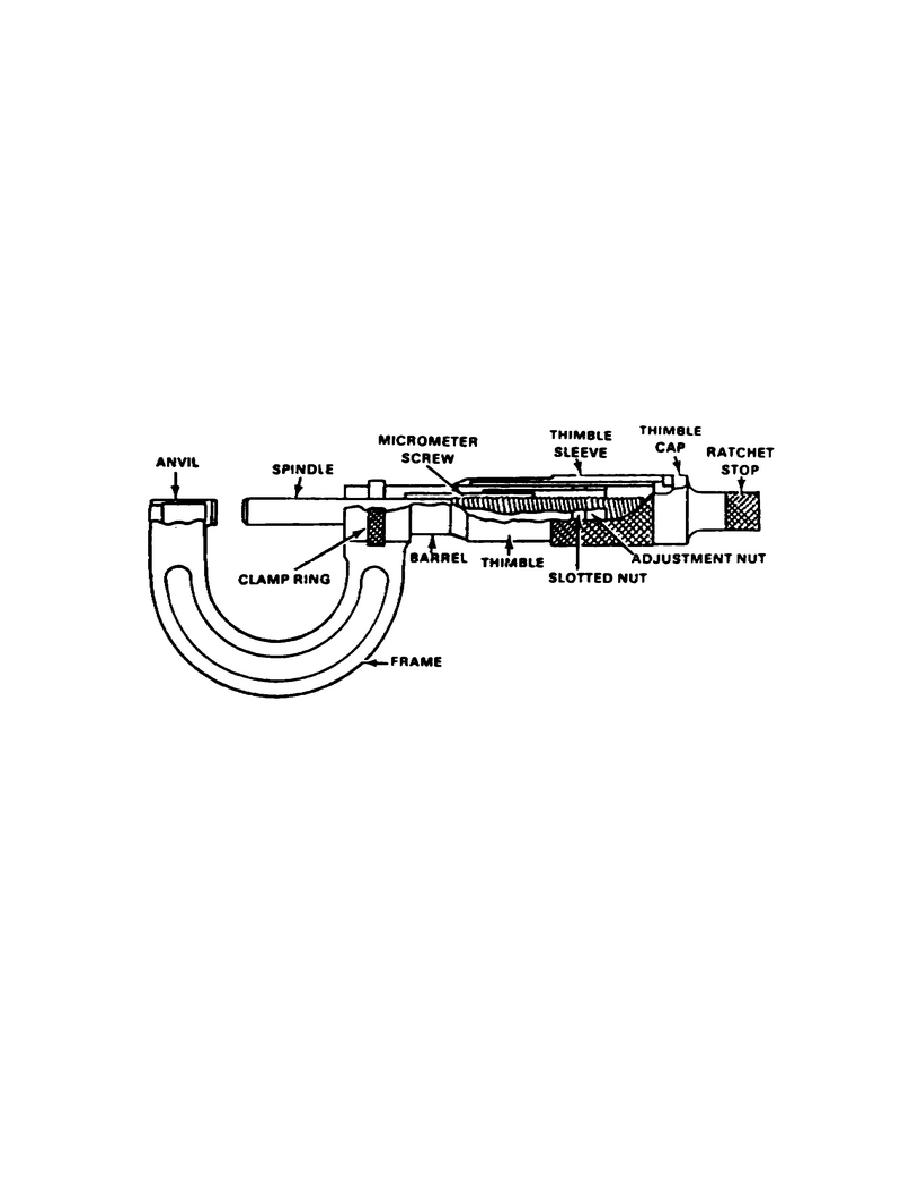

Design

The micrometer, Figure 5, makes use of the relation of the circular movement

of a screw to its axial movement. The amount of axial movement of a screw

per revolution depends on the thread, and is known as the lead.

For

example, a circular nut on a screw has its circumference divided into 25

equal spaces. If the nut advances axially 1/40 inch for each revolution and

is then turned one division or 1/25 of a revolution, it will move axially

1/25 x 1/40 or 1/1,000 of an inch. In the micrometer, the nut is stationary

and the screw moves forward axially a distance proportional to the amount it

is turned. The screw on a micrometer has 40 threads to the inch, and the

thimble has its circumference divided into 25 parts, so one division on the

thimble represents an advancement of 1/1,000 of an inch axially.

FIGURE 5.

MICROMETER CALIPER, CUTAWAY VIEW

Construction

Refer to Figure 5.

You can see the various components that make up a

micrometer.

The following is an explanation of how the components are

assembled to make it work:

a. One end of the U-shaped steel frame holds a stationary anvil. The

anvil is a hardened button either pressed or screwed onto the frame.

b. The unthreaded part of the screw is the steel spindle. The spindle

advances or retracts to open or close the open side of the U-frame.

The spindle bearing is a plain bearing and is part of the frame.

6

Previous Page

Previous Page