Lesson 4/Learning Event

Thread

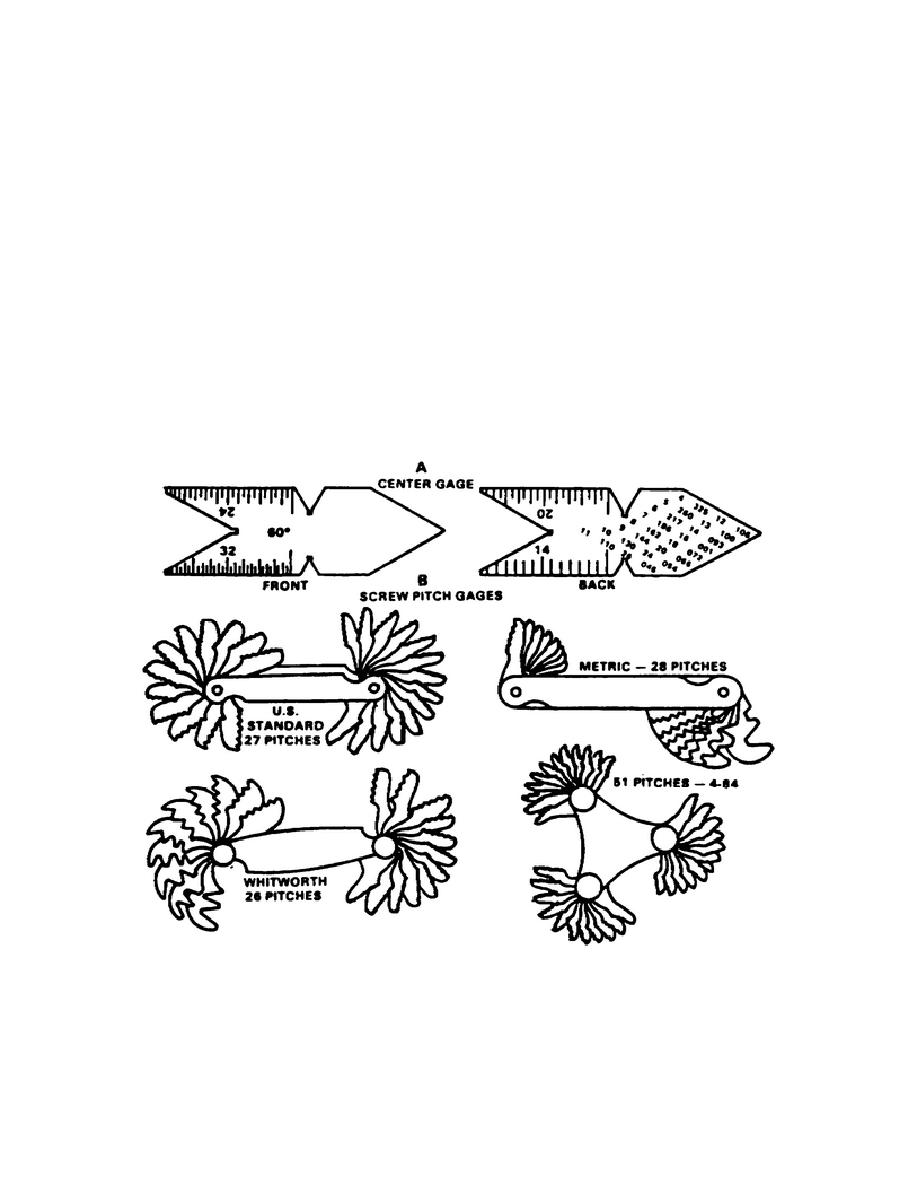

a. Center gages, Figure 51, Part A, are graduated in fourteenth,

twentieth, twenty-fourth, and thirtieth of an inch. The back of the

center gage has a table giving the double depth of thread in

thousandths of an inch for each pitch. This information helps you

determine the size of tap drills. Sixty-degree angles in the shape

of the gage are used for checking Unified and American threads or US

standard threads and for checking thread cutting tools.

b. Screw pitch gages, Figure 51, Part B, are made for checking the

pitch of US standard, metric, national form, V-form, and whitworth

cut threads.

These gages come grouped in a case or handle, like

thickness gages. The number of threads per inch is stamped on each

blade. Some types have blade locks. The triangular shaped gage has

51 blades covering a very wide range of pitches, including 11 1/2

and 27 threads per inch for V-form threads.

FIGURE 51.

CENTER AND SCREW PITCH GAGES (PARTS A AND B)

70

Previous Page

Previous Page